Generator Maintenance

Generator Maintenance

eeping the AC generator running while traveling is a very important part of any motorhome trip. Even if you usually stay at campgrounds with full electrical hookups, the generator still has an important function. Many owners use the generator while driving to keep the rooftop air-conditioners and the refrigerator going. In hot weather the dash A/C unit is not usually capable of keeping you cool while driving, so the generator becomes not only necessary but a more practical option of cooling your motorhome.

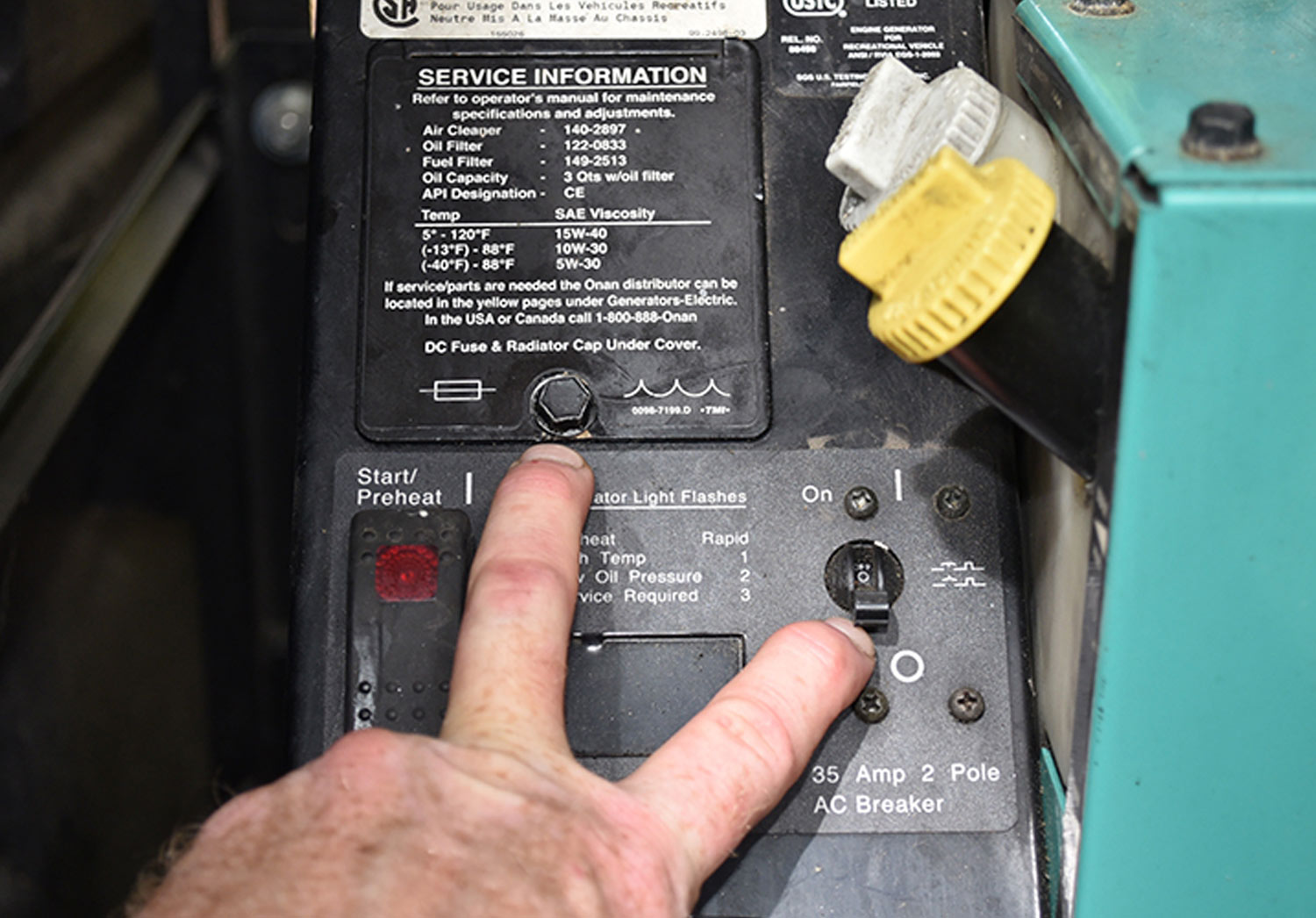

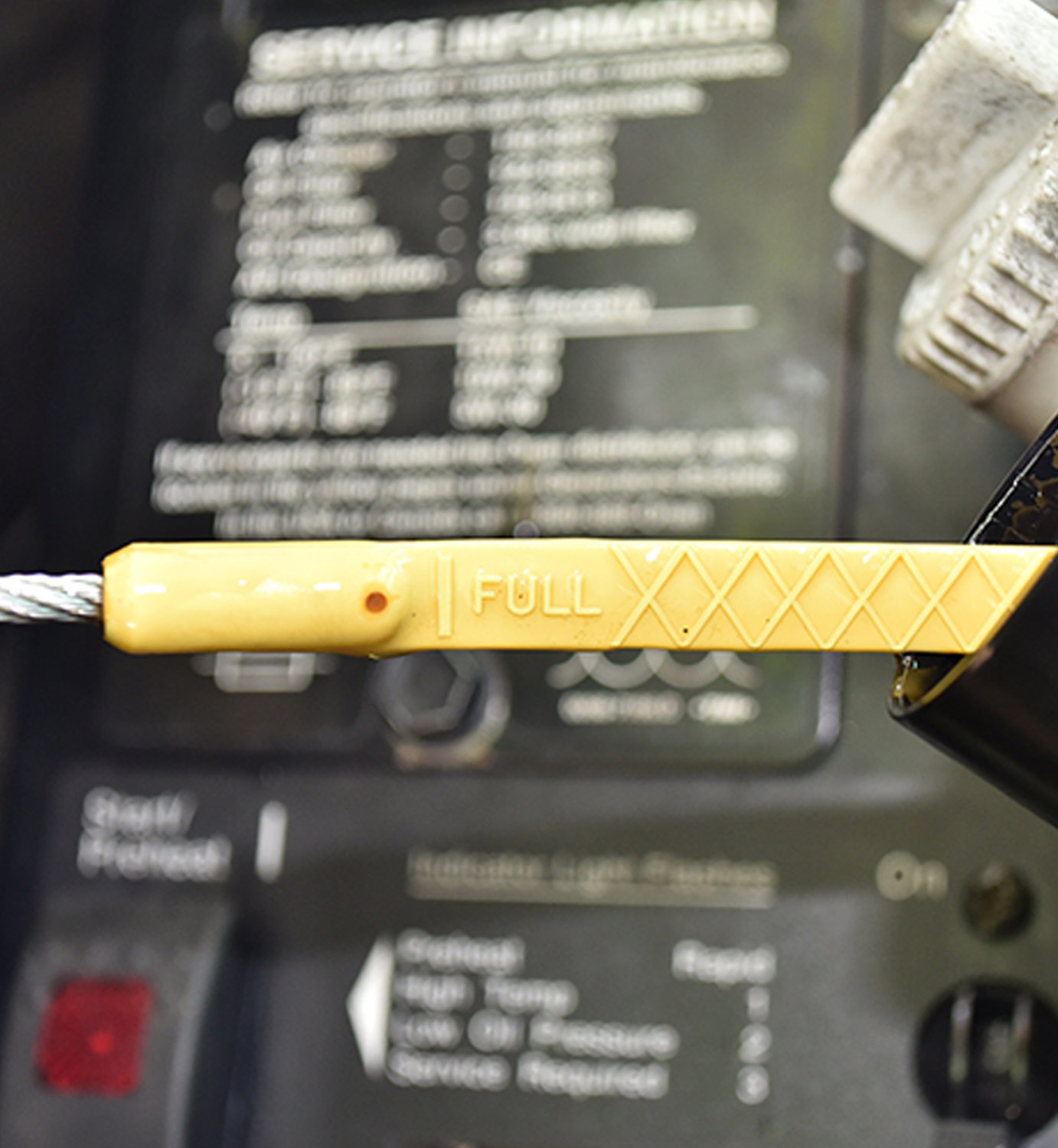

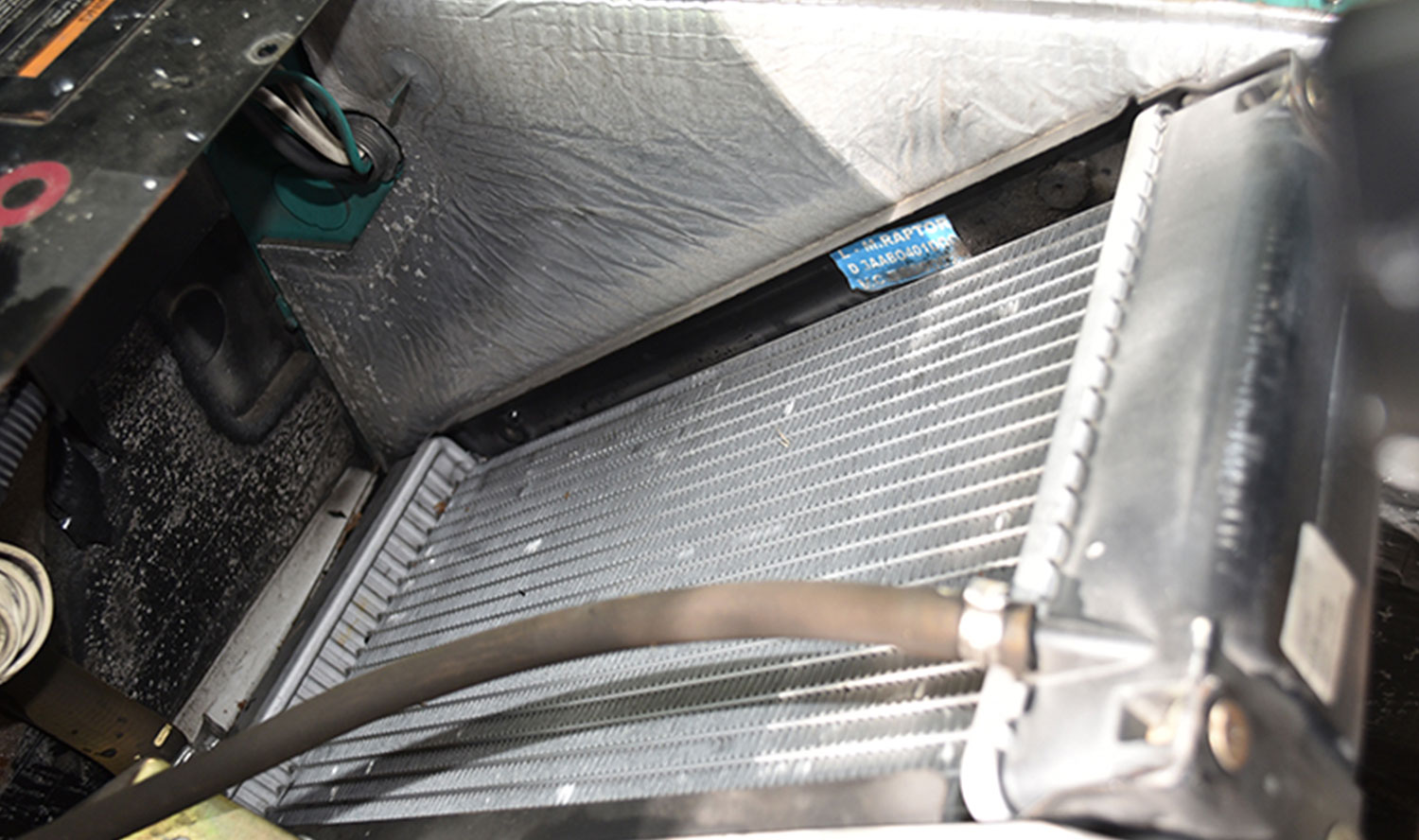

And, it does so on a reliable basis — so long as you maintain the genset and perform service on a regular schedule. None of the requisite maintenance items for a diesel generator — changing the oil and oil filter, cleaning the spark arrestor and changing the air filter and the fuel filter — is especially taxing, but kept up to date, such maintenance will help to ensure that when you hit the “start” button it does what you want. To help guide you in the process, we’re going to illustrate what each step requires; in addition, we’ll show how to drain and flush the radiator and replace the coolant. Each of these service items have a schedule in the Onan owner’s manual so you may not need everything we are doing.

We picked these items because they are the most frequent and easy to do for an owner. If you have a different generator or a gas-powered generator the steps may be similar, but there could be a different service interval and different items that need to be serviced. So, make sure you check the owner’s manual or look up the exact model of your generator online to find the recommended maintenance schedule that applies to your unit and follow it. Also in the manual you will find the specifications for what type of coolant to use, as well as the oil viscosity.

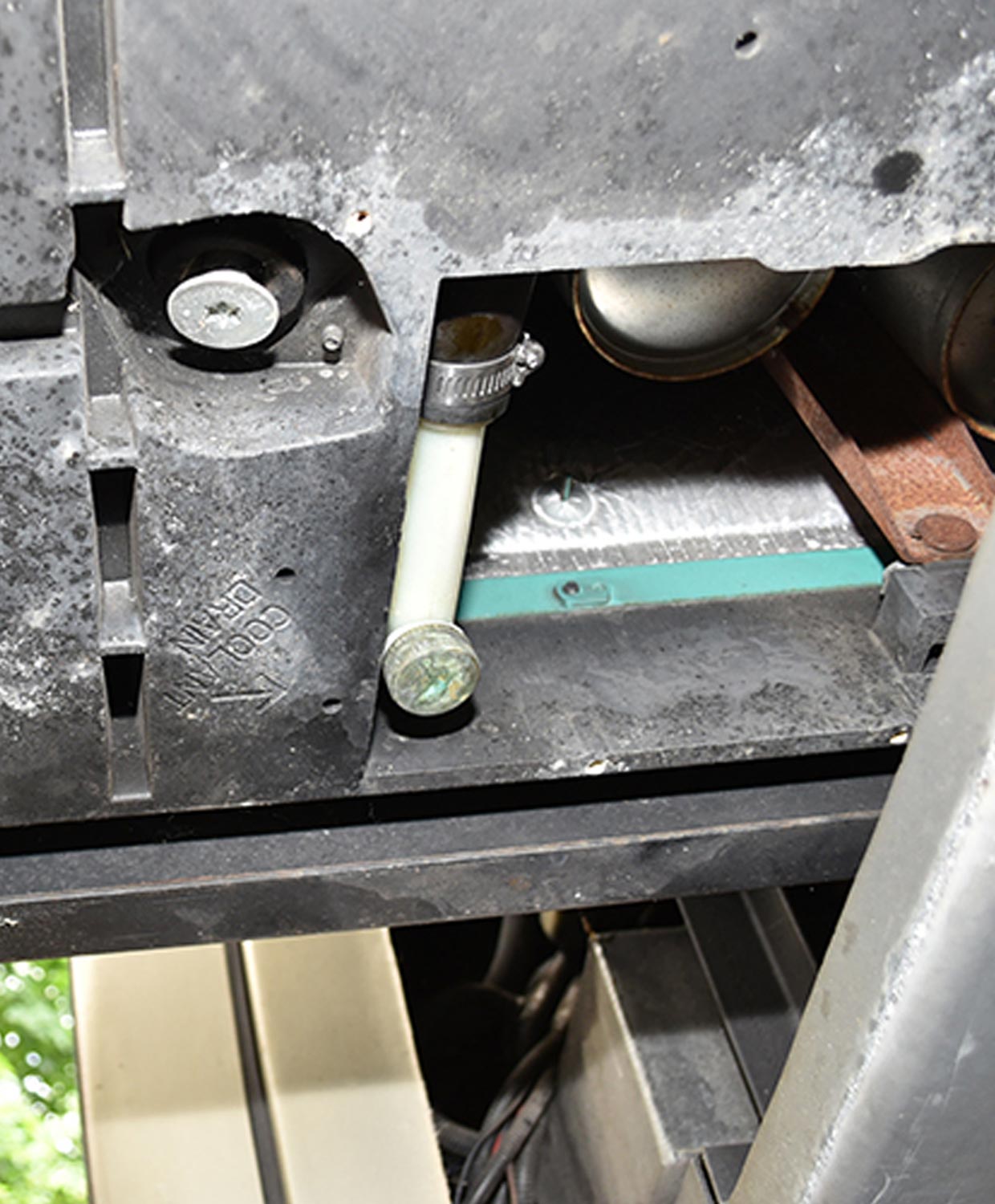

To keep things simple, we suggest you use the same coolant in both the chassis engine and the generator so you can carry one gallon of the same coolant and it will work for either application. Of course, you need to check the owner’s manual and use an approved coolant type. For this generator, Onan simply specifies that you need to use an ethylene or propylene glycol coolant with no stop-leak additives.

Safety is the top priority on any DIY project so make sure you utilize stationary jack stands under the frame of the chassis — do not rely solely on the built in hydraulic or electric jacks. It is fine to use them to raise the coach high enough to place the jack stands. And, of course, make sure the jack stands are rated for at least the weight of the axle being supported.

The tools required for this type of service are basic. Other than the jack stands, most any DIY mechanic will have an oil filter wrench and sockets/wrenches to perform this work without having to purchase anything special. We purchased the oil and coolant as well as the oil filter at a local auto parts store but the Onan air filter and fuel filter is specific to the generator, so you will have to get that online or at a local RV dealer or Onan service center. Also, you will need two gallons of distilled water for flushing the radiator.

The belt change, hose replacement and thermostat replacement are considered more advanced and should most likely be performed by a qualified mechanic

Clean Spark arrestor least

Replace Fuel Filter

Check Coolant

Replace radiator cap; perform at every two years

Replace engine belt; perform at least every 5 years

Clean crankcase breather; perform at least every 5 years

Replace hoses and thermostat; per form at least every 5 years.

Clean Spark arrestor least

Replace Fuel Filter

Check Coolant

Replace radiator cap; perform at every two years

Replace engine belt; perform at least every 5 years

Clean crankcase breather; perform at least every 5 years

Replace hoses and thermostat; per form at least every 5 years.