here are a lot of systems on a travel trailer or fifth wheel that we often take for granted will work when we need them–from the blissful, cool breeze of the air conditioner when it’s hot outside to a warm meal courtesy of the microwave oven. If these components don’t work properly, however, it can be aggravating — but won’t doom that long-planned getaway.

The same can’t be said of the brakes on that towable. A tow vehicle may have been designed with enough capacity and power to pull a trailer, but it wasn’t designed to have to continually slow and stop all the weight of the trailer. Put simply, the braking system on a trailer can make the difference between a stress-free journey and a potentially dangerous one.

Regular maintenance is crucial for keeping the electric brakes on a travel trailer or fifth wheel working properly. Many manufacturers, in fact, recommend adjusting the brakes every three months to compensate for friction-surface wear. It’s not a fun job, especially if you’re in the midst of an extended trip, but it’s a necessary evil.

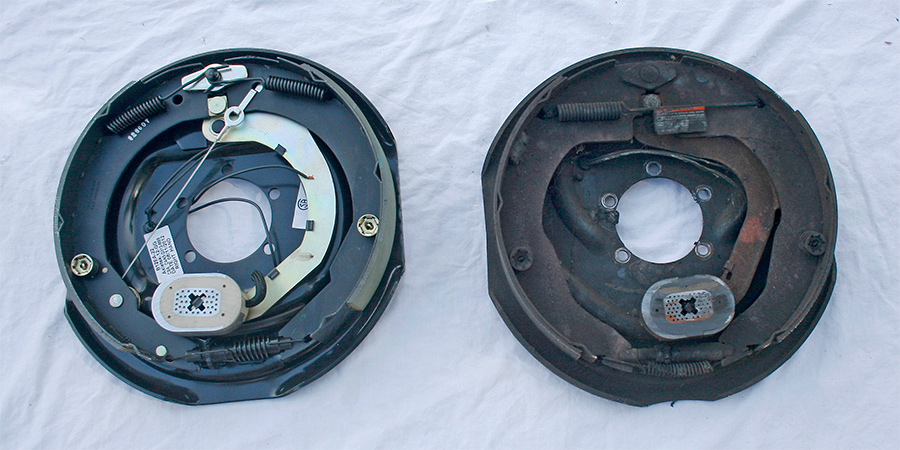

Basic brake system operation is similar for standard electric brakes and the Lippert self-adjusting system. Each brake has two shoes lined with friction material, joined by a star wheel adjuster. When the tow vehicle’s brakes are applied, the brake controller sends an electric signal to the brake assembly electromagnets, which connect to actuating arms that move the shoes outward to make contact with the drum armature However, each Lippert Forward Self-Adjusting Brake assembly adds a mechanism that optimizes the shoe locations during each forward stop to gradually spread the shoes outward, compensating for friction-lining wear. This is accomplished with a cable and pulley system between the shoes, attached to the brake adjusters.

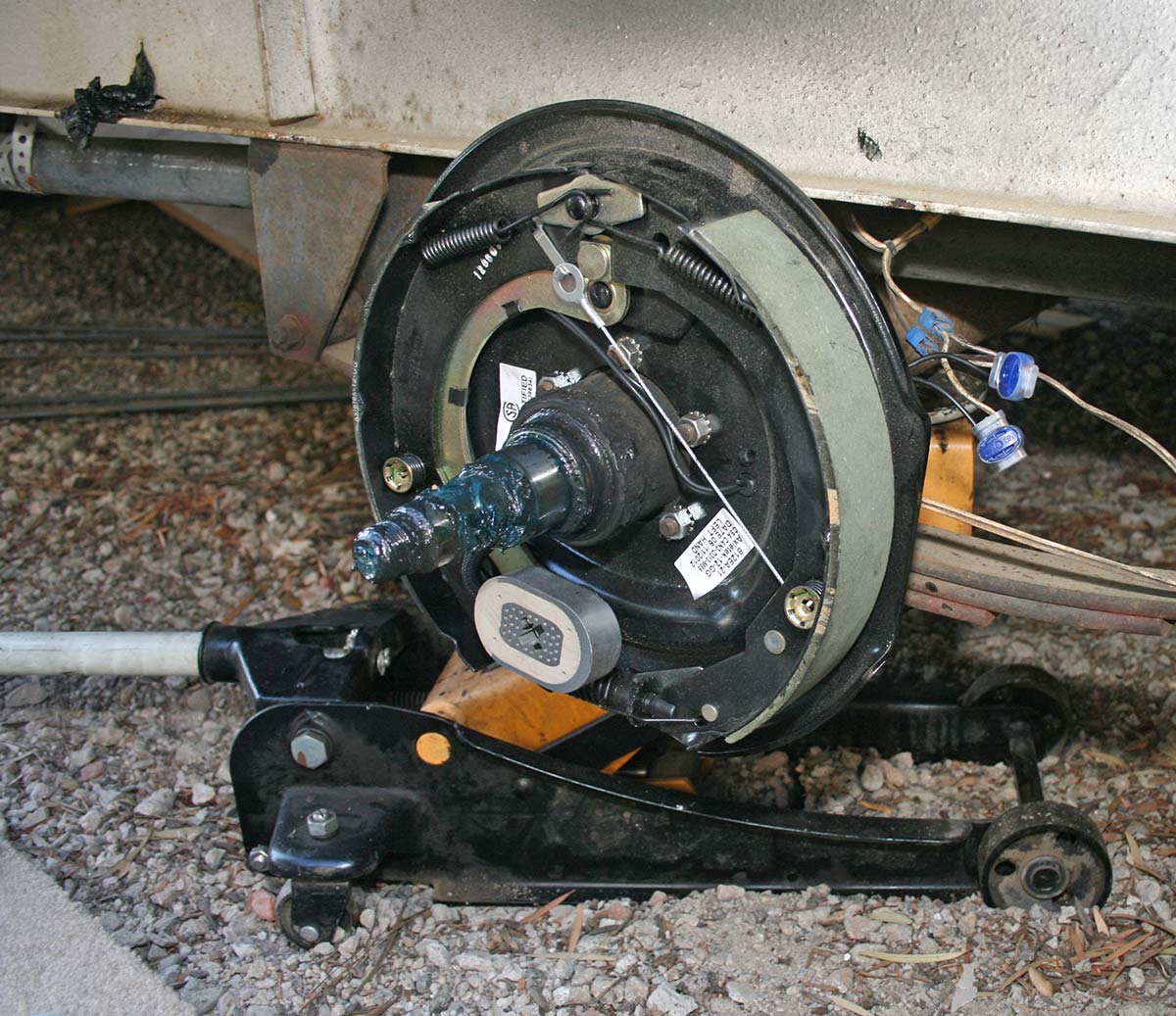

Easy, Do-It-Yourself Installation

The Lippert Forward Self-Adjusting Brakes install in the same manner as standard brake assemblies. The job takes about an hour per wheel and can be done by RV owners who possess basic mechanical and wiring skills. Highlights of the installation are shown here on a Forest River Wildwood 34-foot fifth wheel. As we discovered, by the way, the installation also provides an opportune time to re-grease wheel bearings (see “Keep Rolling” elsewhere in this issue for detailed information on this subject).

The Lippert brake assemblies are side-specific for proper self-adjustment. A white sticker on each backing plate identifies them as “left” or “right.” As back-up, the forward-facing primary brake shoes have shorter brake linings than the rear-facing secondary shoes. Although the brakes are self-adjusting, Lippert recommends seating/burnishing new shoes to conform them to the drum armature. This break-in period is accomplished by setting the brake controller at mid-gain and using its manual lever to slow the trailer from 40 mph to about 20-25 mph (without applying the tow vehicle’s brakes). The process should be limited to one-mile intervals to allow the brakes to cool between bedding sessions. Between 20 and 50 of these break-in cycles will properly seat the shoes and magnets. The driver should feel the improvement in braking power as the shoes conform to the drums. (Additional installation and maintenance information is in the Electric Brakes Owner’s and Service Manual on Lippert’s website or on the Lippert mobile app).

The Lippert self-adjusting brakes can theoretically pay for themselves over time by optimizing brake-lining and magnet wear; this is far better and safer than compensating for trailer brake wear by increasing gain on the brake controller. The time saved by not having to crawl under the axle to adjust the brake shoes — or pay someone to do it — is an added bonus.