inter can be a special season to travel in an RV — and when the temperature drops, modern comfort heating systems will keep the interior cozy. Granted, there are a number of ways to warm up the interior, but most RVers rely on their LP-gas furnaces. Everything is copesetic when they work, but when something goes awry, it can be a challenge to keep occupants comfortable inside the RV. That’s why it’s important to have at least a basic understanding of what can go wrong and how to mitigate the situation — even when on the road, far from service centers.

It’s not possible to have an effective HVAC system without a source of heat. Murphy’s Law suggests that a furnace will only fail when it’s needed the most. Keeping an eye on internal components and knowing what to look for when a furnace fails — or becomes erratic — can make a big difference in whether you’ll be shivering inside a blanket or enjoying the interior space in comfort. The following applies to typical furnaces found in RVs. (Hydronic and Truma models are not covered here.)

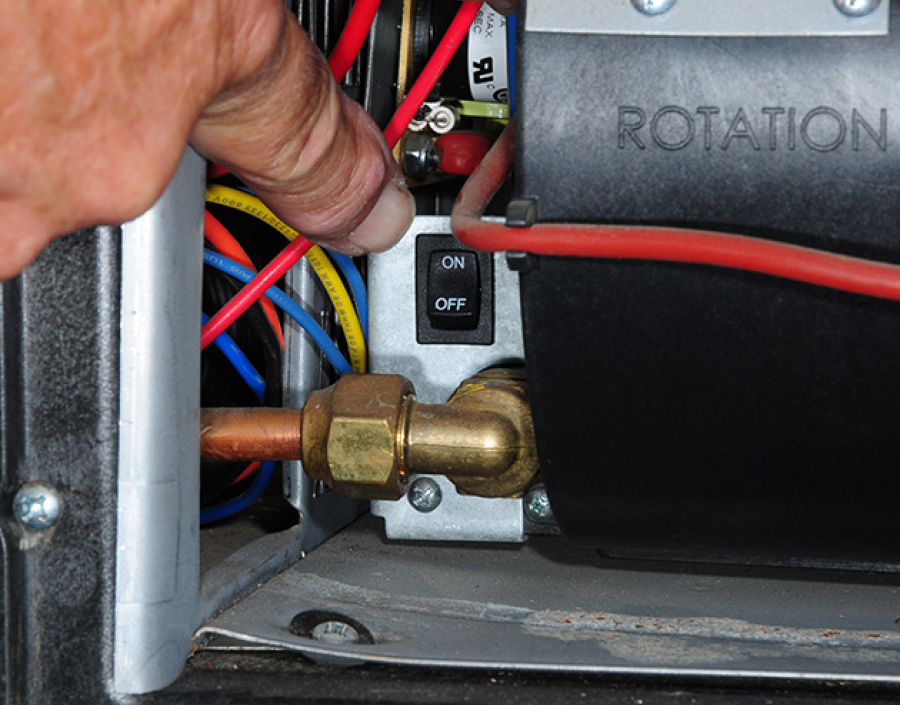

If you find yourself far from a service center and do not have access to a manometer, a quick way of checking for a drop in gas pressure is to ignite the burners on your stove and turn the furnace on; if the burner flames drop considerably in size or completely go out, the pressure regulator is likely defective.

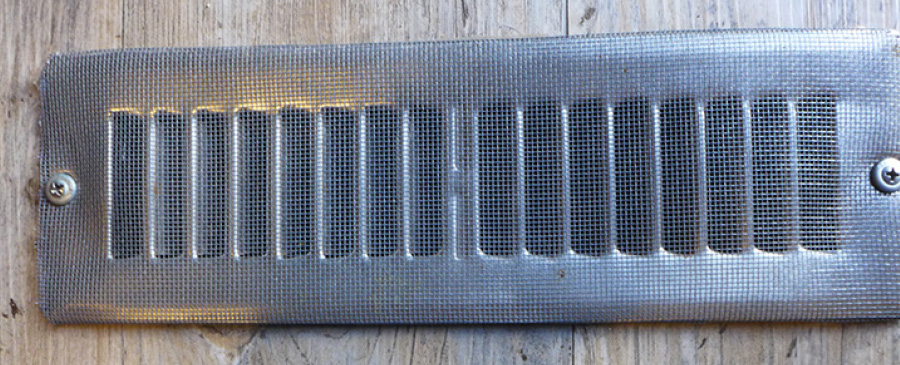

Another possible blockage could be traced to bug screens attached to the outside of the furnace at the intake and discharge ports. Manufacturers do not recommend this as it can impede air intake and discharge if the screens are allowed to plug up. If you insist on using these screens, make it a point to inspect the surface for blockage on a regular basis.

Floor registers can collect an unbelievable amount of dirt over time — including pet hair, which can cause a serious problem by blocking the air flow through the ducting. If you have pets that shed and are concerned about the integrity of the floor registers, remove them and apply a coarse screen material that will not impede the air flow, but will keep pet hair and debris out of the ducting — and inspect/clean frequently to make sure air flow is not impeded. Some fifth wheels have a return air vent in the basement, which can be blocked unintentionally by nearby stored items. Become familiar with the return air configuration and take measures to keep the vent clear at all times. If the return air vent is located in the galley, remove it and check periodically for anything that could have been dropped out of a drawer and possibly impede air flow.

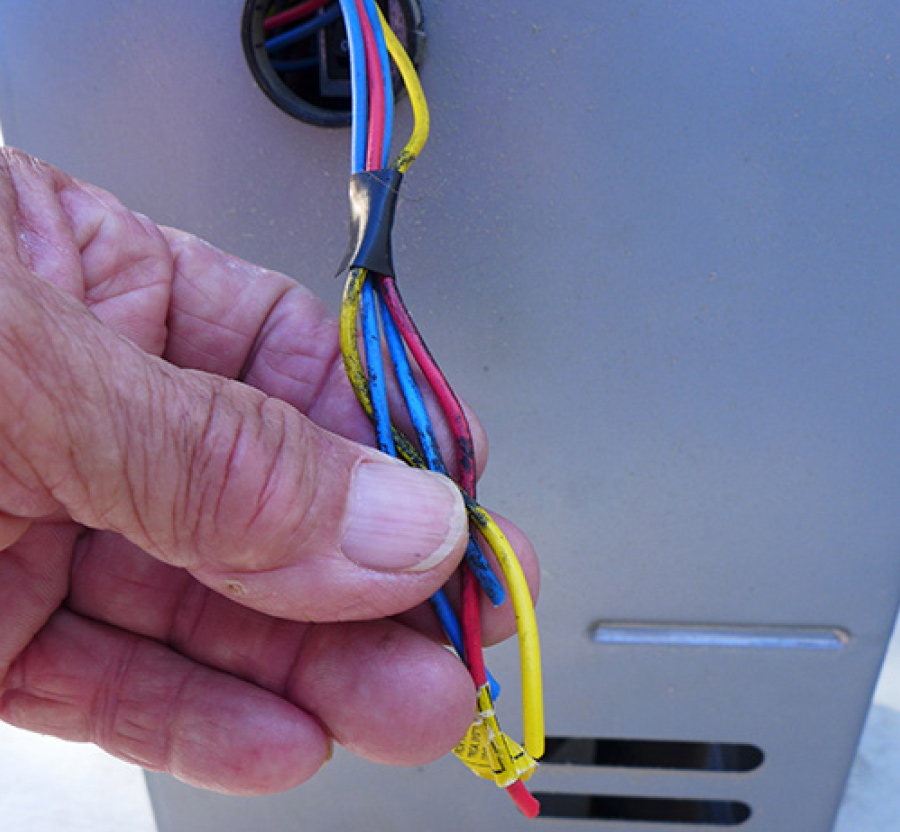

In the old days, wall thermostats were basic with an on-off switch and a lever to set temperature. For these models, normally there are two blue wires coming from the furnace, which must be connected. Mechanical thermostats are still around but are not super accurate; owners learned to adjust the set points based on trial-and-error and interior comfort. If you suspect that the thermostat has failed, it can be removed from the wall and a jumper wire can be placed across the two terminals to test-activate the furnace. Keep in mind that every furnace has a fan-control board or time-delay relay and you will need to wait 20 or 30 seconds for it to start, and up to three minutes for the fan to shut off after the flame ceases.

Modern digital thermostats that control the air-conditioner(s) and the furnace are a bit more complicated. You can remove them to check for loose connections; testing is accomplished using an accurate voltmeter. In many cases, the blue furnace wire will go to the air-conditioner control board and not the thermostat.

Thermostats integrated into touch-screen control panels are more complicated and require testing by a trained technician, although many resets and testing can be accomplished right from the screen. Companies like Thor Industries, which includes a touch-screen panel to control systems in many of its RV lines, provide excellent support over the phone and online.

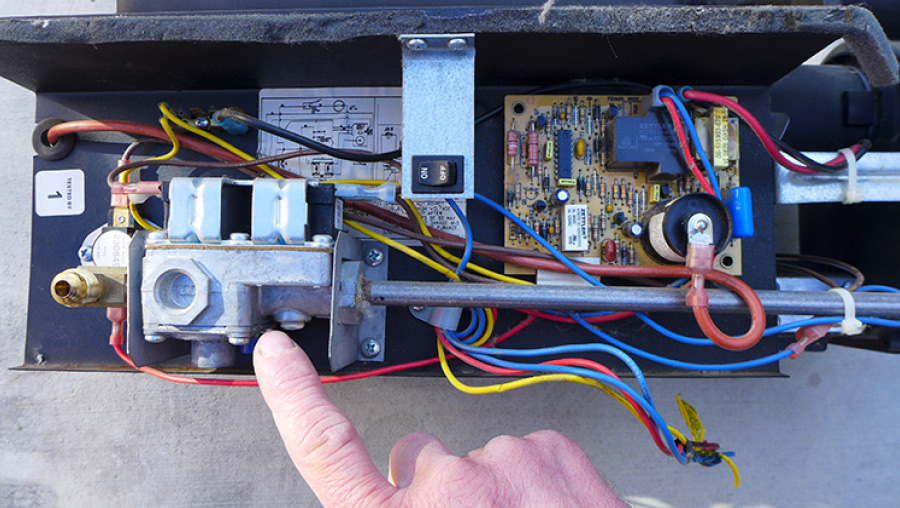

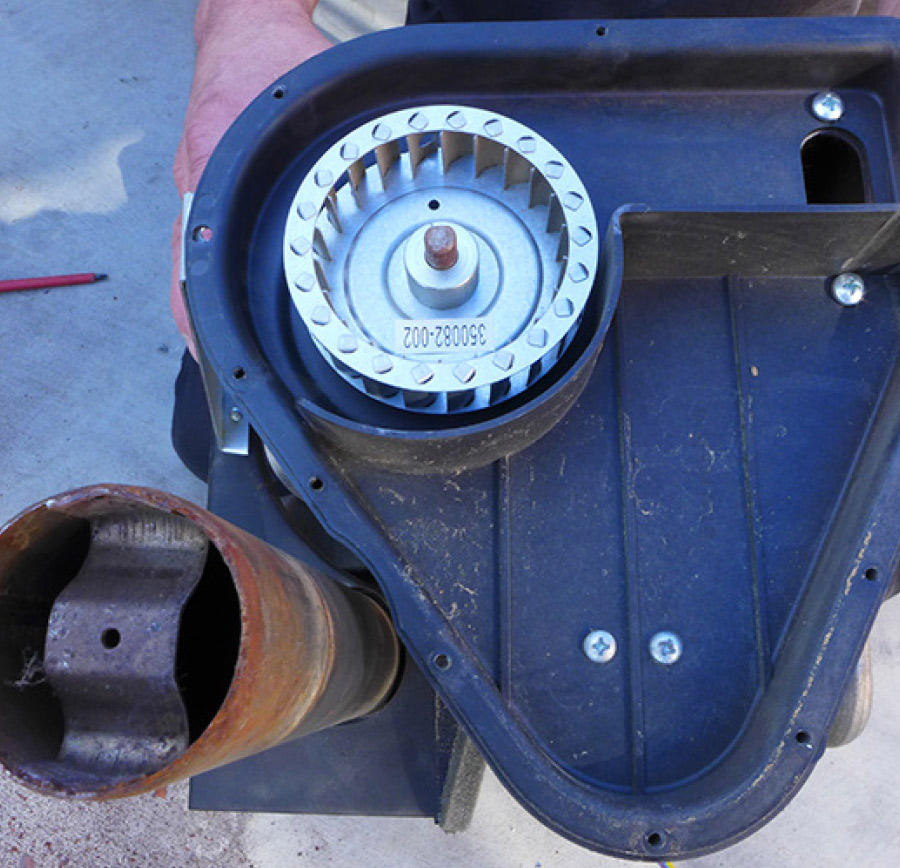

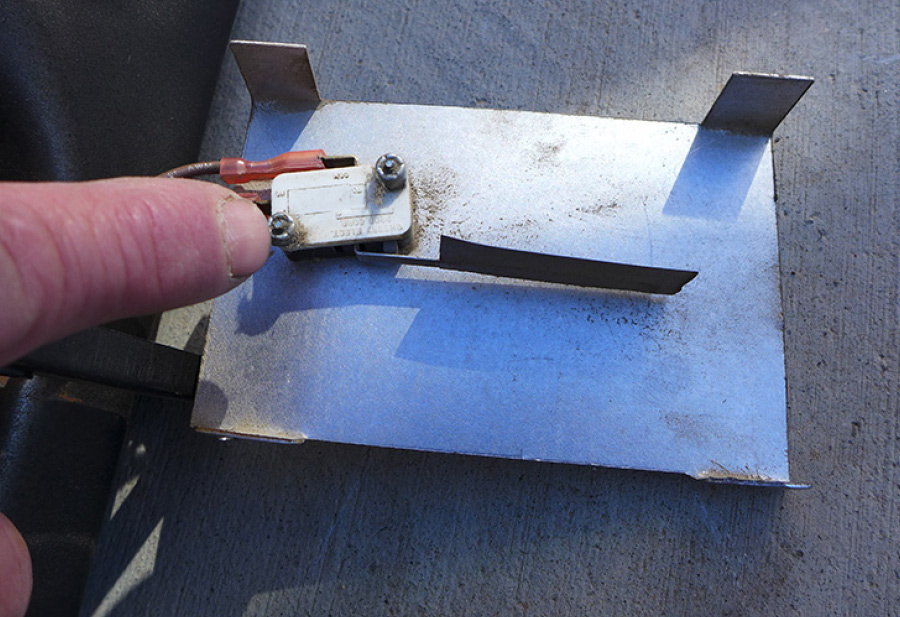

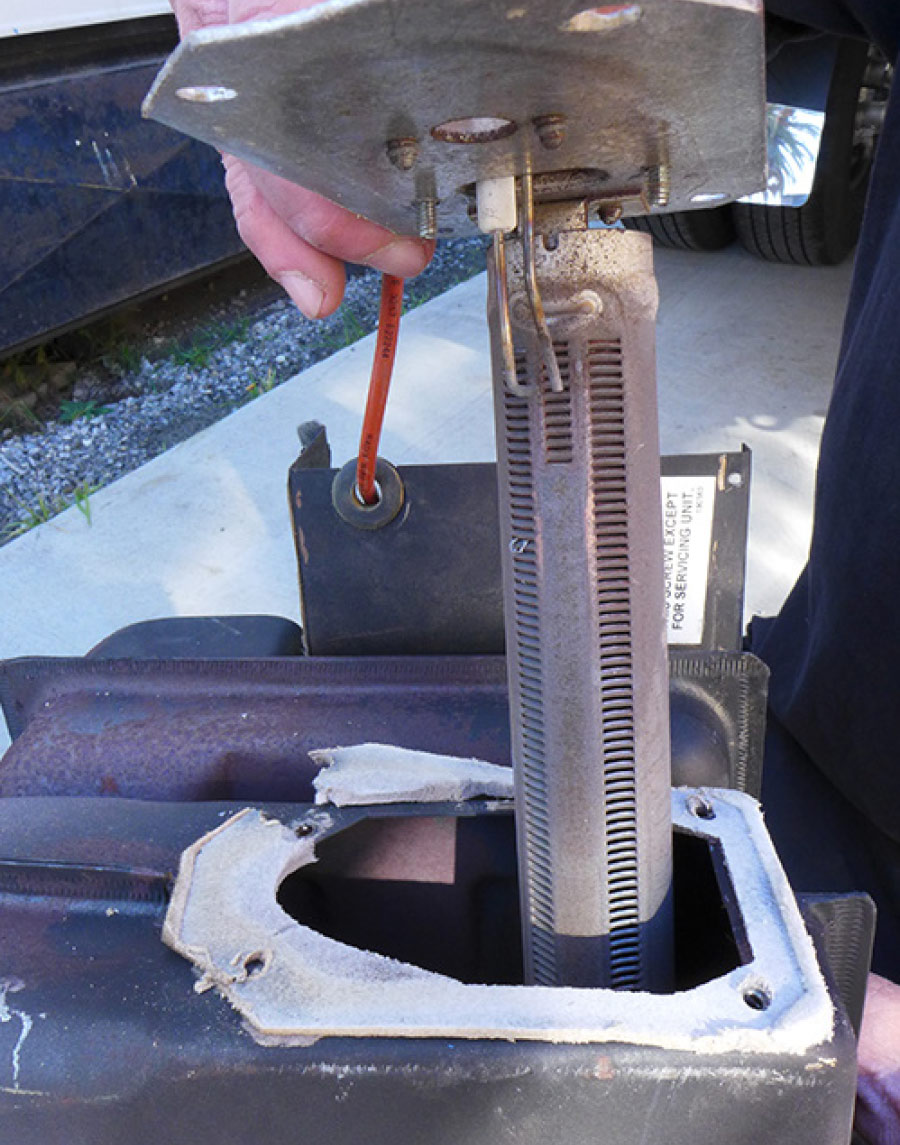

Gaining access to the circuit board and sail switch is fairly easy on units with an outside access panel, but units without this feature require complete removal. Test for voltage flowing through the sail switch to the circuit board if the indicator light on a circuit board is not lit. If you have an older-style PC board without an indicator light, you can test the voltage at the circuit board that comes from the sail switch or from the limit switch, depending on the model of your furnace. The limit switch is a thermal disc that will shut the furnace off when the burner heat exceeds set limits. The sail switch closes the circuit when the air flow from the fan is strong enough to move the flat portion on the switch arm. This is a safety device that will prevent flame ignition if there is not enough air moving through furnace. Should the combustion chamber overheat, the limit switch will shut down the power to the circuit board so that the flame goes out and allows the furnace to cool down. This usually only occurs when there’s a problem with venting (see No. 5). It’s fairly rare to find a limit switch that has failed.

Subsequent furnace models morphed to the use of a Fan 50 Plus circuit board, which was designed to eliminate the time-delay relay (see No. 10) and control the fan motor when there was a lack of ignition. Manufacturers transitioned to the current fan control circuit board, which is found on all furnaces today.

Most modern circuit boards can be tested with a tool utilized by RV dealerships and repair centers. You may be able to take the board to the local shop and ask if its technicians will test it. The best replacement circuit boards are made by Dinosaur Electronics.

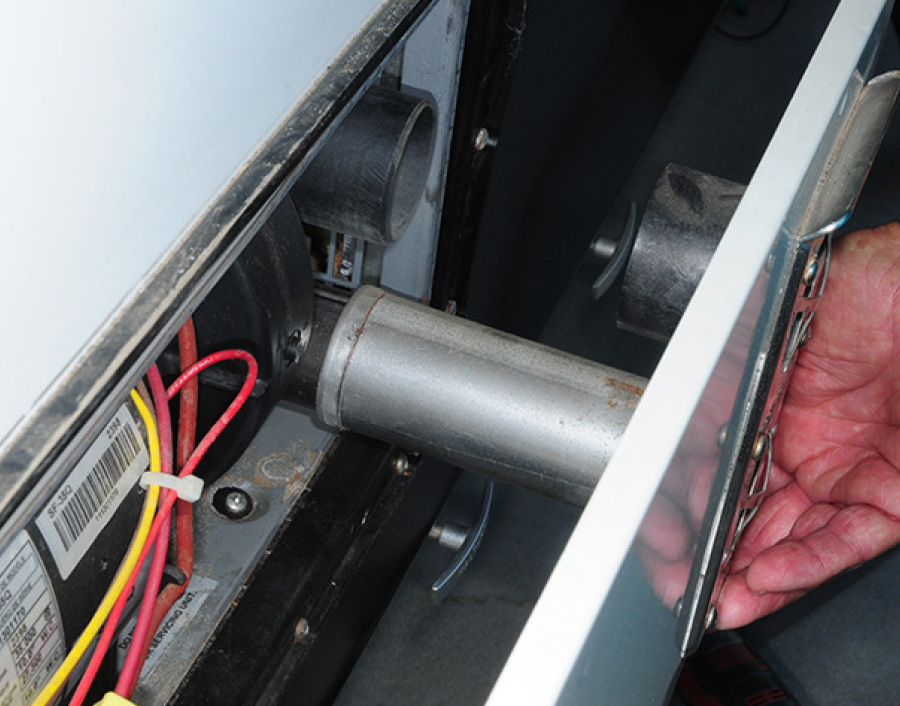

Remove the furnace and find a suitable bench or location to clean all the parts in the combustion chamber. Cleaning soot from the furnace will require a large volume of air pressure, not to exceed 200 PSI. The tricky part is removing the burner from the furnace for cleaning. Keep in mind that rust can be an issue with some older burners, closing the slots (in the burner) over a period of time and causing an improper flame. Blow air through the intake and discharge vents and through the front of the furnace after removing the electrode assembly to gain access to the combustion chamber. This is very messy, and black dust will go everywhere; wear a mask.

Extreme cases of improper ignition could be traced to the burner orifice; seek professional help if you are not familiar with this procedure. Another cause of improper ignition could be LP-gas pressure (see No. 1). Use caution when working with combustion systems; it can be very dangerous.

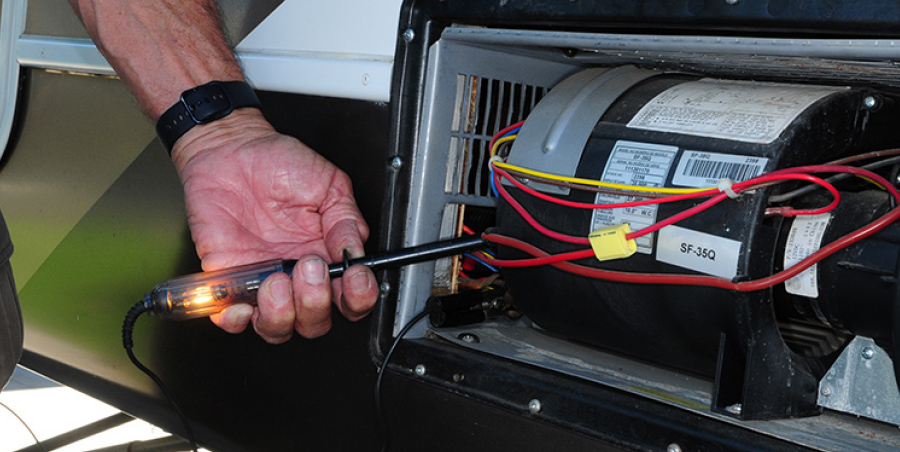

Normally, a defective time-delay relay will not allow the furnace blower motor to come on. There are instances when the blower motor will cycle several times before remaining off or on. The time-delay relay functions by sensing voltage via a signal from the thermostat. If you suspect the time-delay relay is defective, use a voltmeter to check power coming into the relay and to the thermostat side of the relay. If it has power at both terminals, then the relay could be defective, providing you already confirmed that the ground to the relay is adequate. The ground on the relay is usually a short wire running to a ground block and can be checked visually. When replacing the time delay relay, be sure that you get the proper one for the particular furnace; they are not interchangeable.