owing fifth-wheel trailers is popular for several reasons — not the least of which is the inherent stability when on the road. Then, too, there’s the ease of hooking up without having to handle/store heavy pieces of hitch equipment. To reap the benefits, however, a fifth wheel hitch must be installed in the bed of the truck and usually occupies a big chunk of the bed space. It’s also a heavy and bulky piece of equipment, making it difficult to remove when additional bed space is needed.

Fifth wheel hitches typically have a saddle with a latching mechanism that accepts (and locks) the kingpin built into a box mounted on the front of the trailer. While this approach is certainly tried and true, PullRite (pullrite.com), a builder of high-quality conventional saddle-style fifth wheel hitches, also offers an alternative, the SuperLite, which takes the sting out of removing and installing heavy, bulky hardware while focusing a completely different approach to hooking up.

To fully appreciate the system, I assisted during the installation of a PullRite SuperLite (model #2400; $800 street price) on a 2023 Ford F-250 using the company’s proprietary SuperRail Clean Bed Technology mounting system ($750-850 street price). This rail kit (part #2332) is comprised of custom frame brackets that are designed to bolt into existing holes in the Ford frame. Custom rails are then pinned to these brackets through the floor of the bed. When the pins are released, the rails can be removed completely from the bed, leaving the entire surface free to haul stuff; the SuperLite hitch, which only weighs 50 pounds, can be quickly installed and removed from the rails — a simple one-person operation.

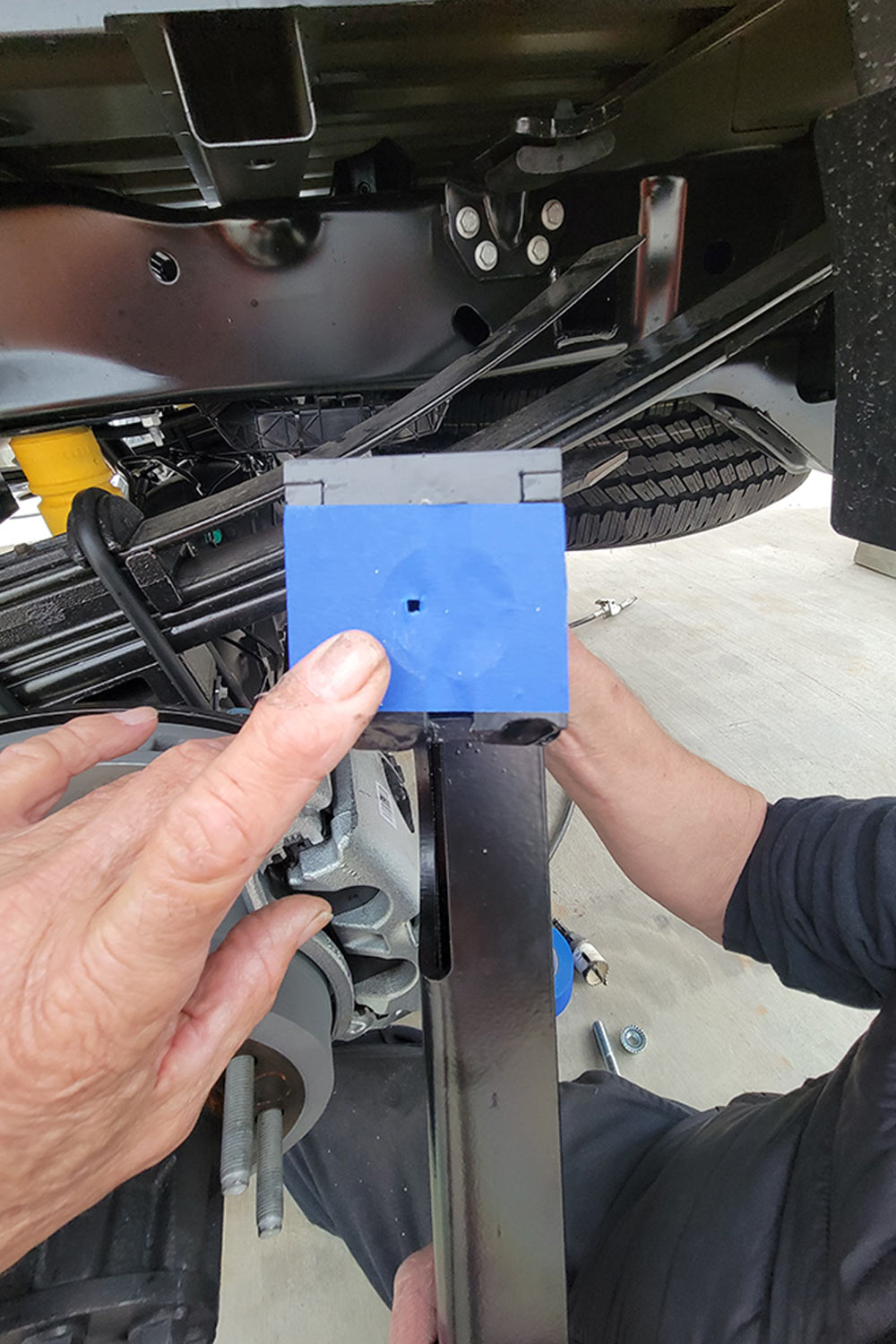

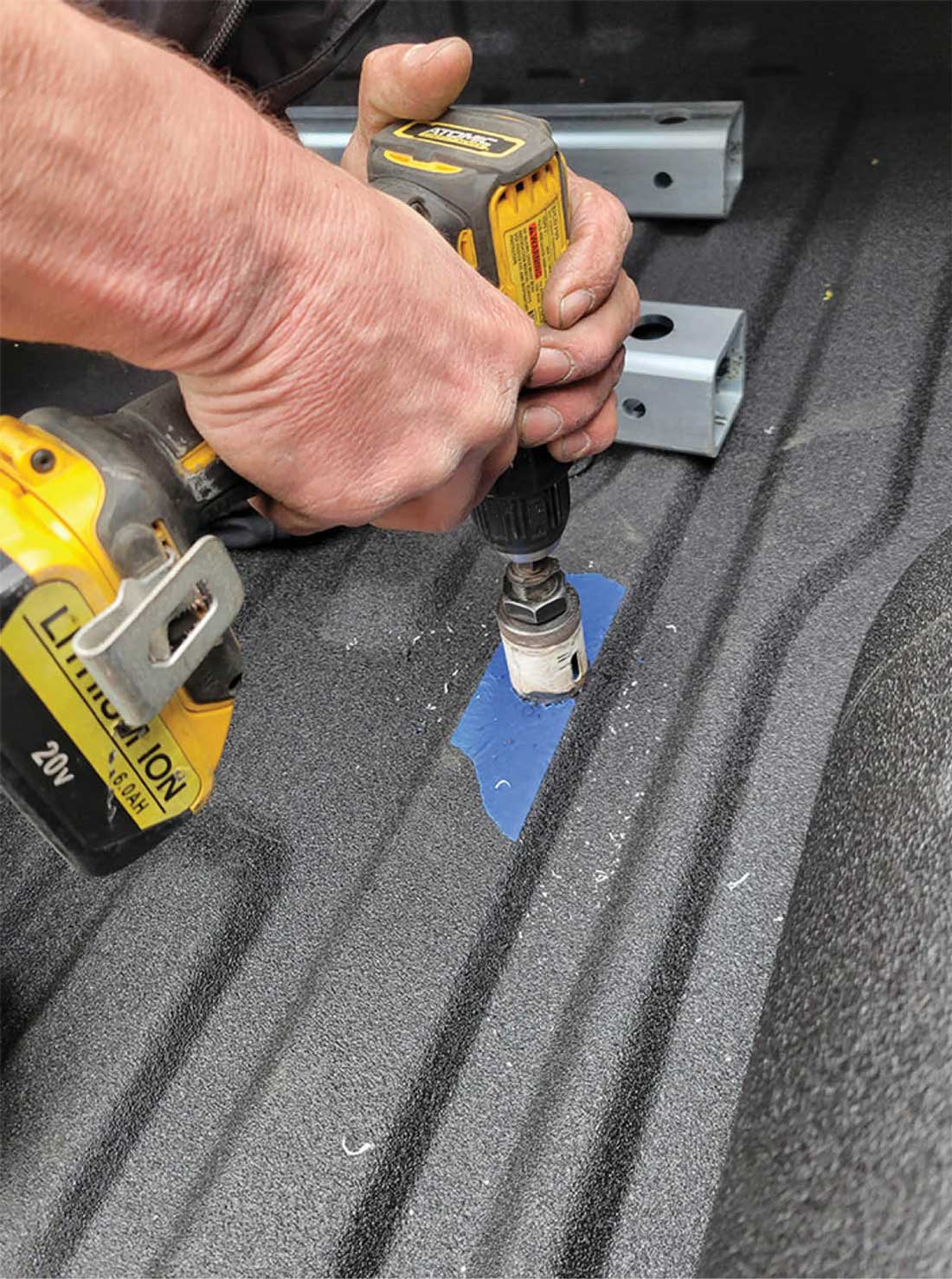

Installing the brackets below the truck bed seemed like a straightforward task, based on the clearly presented instructions. Taking accurate measurements and marking hole locations in the bed is paramount, especially considering the new truck rolled off the dealer’s lot only a few hours before the installation. The bed was lined with a rubberized material and there was very little room for mistakes when drilling through the aluminum bed. We used blue masking tape to mark where the holes should be drilled through the bed in order to line up with the holes (for the locking pins) in the frame brackets. Following instructions very carefully, we measured three times to make sure that we had the holes in the right locations — there’s little room for error as the pins for the rails need to be pushed down into a slot without resistance and allow for a quarter turn to lock them in place. In other words, if the hole was slightly off, the pin was not going to fit properly.

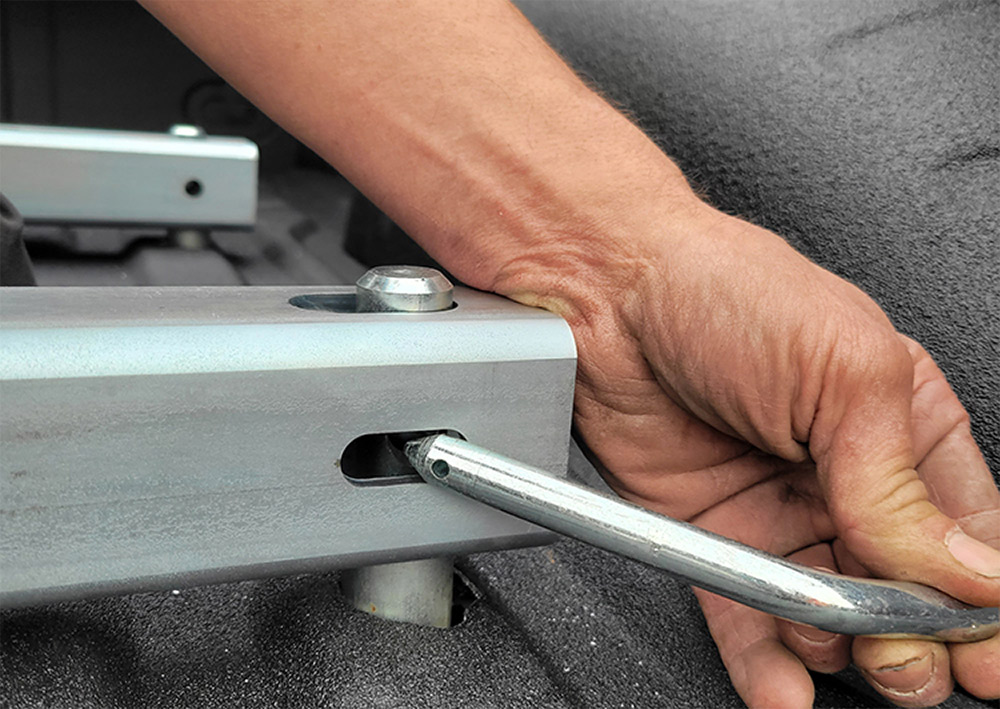

Once the 1 5/8 holes were drilled through the bed, the rest of the process went without hiccups, torquing the frame bracket bolts to 150 ft.-lb., according to the instructions. With the brackets in place, the pins were inserted through bed and the SuperRails were secured before setting the SuperLite hitch on the rails and locking in place with four additional pins. Since the hitch is so light, the process to line up its tabs with the rails requires little effort — and goes smoothly without any resistance.

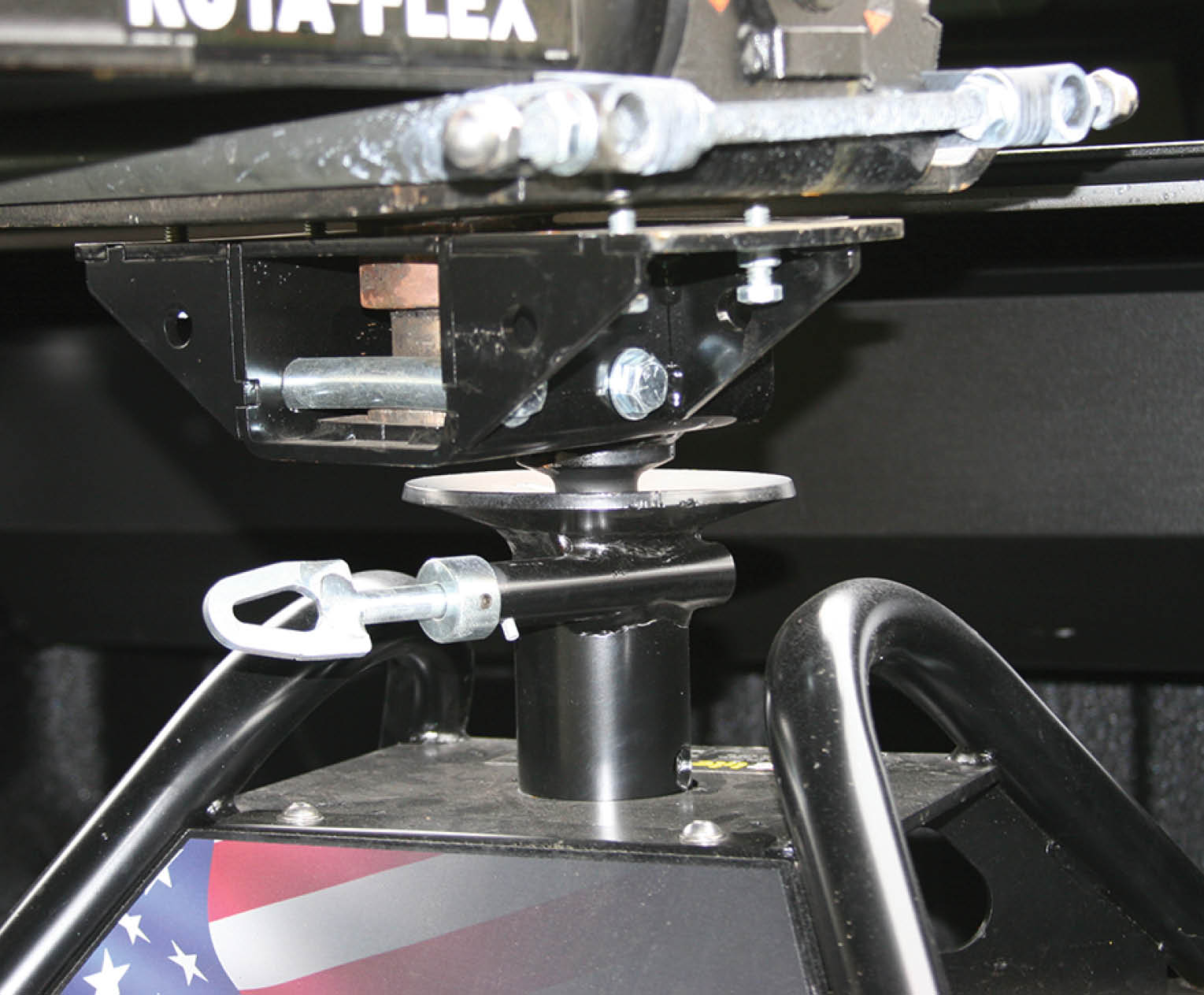

An adapter must be bolted to the kingpin box which, in effect, moves the bulk of the hardware from the truck bed to the fifth wheel. In this case, the fifth wheel was factory-fitted with a Curt Rota-Flex pin box, requiring the use of a different type of an adapter that can be ordered with the hitch. This adapter (part #4446; $90) can be installed in about 30 minutes, requiring no modifications. It’s designed to isolate movement of the Rota-Flex pin box, which is necessary to allow the SuperLite hitch to function properly. The low-profile design of the adapter functions like a gooseneck hitch — without the additional leverage placed the front of the fifth wheel, which can lead to breaks in the steel infrastructure.

The adapter was simply positioned over the stock kingpin using two bolts to hold it in place. The one on right went in first and was held in place with a 1/2-inch flange nut, which was only hand tightened at first. The second bolt followed after sliding in a reinforcement tube through a larger hole on the left; the flange nut was then snugged by hand. Four set screws were then adjusted to provide a level attitude for the adapter and to make sure it was positioned tightly against the kingpin box. By the way: The ball can be offset toward the front to allow for additional clearance between the fifth wheel and back of the cab in short-bed trucks. The bolts and setscrews are torqued to specifications to complete the fifth wheel part of the installation.

Hitch height can be set at three levels for proper top-of-bed clearance and PullRite recommends that at least 8 inches be maintained; the funnel coupler height can be adjusted by loosening three jam nuts and backing out the bolts. Once the coupler is loose from the base, the clevis pin is removed and the coupler can be lined up in the base using one of the three holes. The bolts and jam nuts are torqued to 45 ft.-lb.

The ability to tow fifth wheels up to 20,000 pounds (5,000-pound pin weight limit) with a hitch that weighs only 50 pounds seems incongruent, but PullRite’s expertise in creating products with exceptional quality and build tolerances makes it possible to change the paradigm when it comes to the utmost in safe fifth wheel towing.

To circumvent cutting and splicing wires on this new Ford pickup, we used a Curt #57008 7-way, plug and play wiring harness ($109.15 on Amazon) that simply connects to the back of the existing OEM connector, leaving both locations active.

This wiring harness kit literally cuts the installation time in half. The hardest part of the installation is drilling the holes, which is really not that difficult. You’ll have to drill a large hole for the receptacle along with four holes for the mounting flange in the bed. Keep in mind that it’s not possible to use steel screws in the all-aluminum bed of the Ford truck because of possible electrolysis between the metals; instead, four rubber inserts are designed to isolate the screws.

The directions call for the removal of the spare tire in order to facilitate enough room to plug the wiring harness into the original Ford 7-way connector, but those with smaller hands should be able work in the area without too much consternation. My cohort in this installation has smaller hands, so he was elected to make the connection. The kit comes with a 7-foot harness, which was long enough to reach the desired location for the receptacle.