ummertime brings hot weather — and most RVers venturing into regions where the temperature soars must rely on their rooftop air-conditioners to be comfortable. Most RVs have one or two air-conditioners, and many are now outfitted with three to keep the inside temperatures cool. While the Btu ratings of these air-conditioners suggest that they are capable of getting the job done, inefficient mating to the roof ducting can compromise the flow and cooling capacity. RV Airflow Systems (rvairflow.com) has designed an aftermarket modification kit that improves efficiency dramatically, while taking the noise level down substantially.

I guess you could say that many systems really need to be redesigned. In fact, some of the newer RVs are getting away from ducted ceilings and using a direct discharge, which manufacturers claim is more efficient. For those of us with older RVs, installing the RV Airflow Systems foam changes the paradigm.

Making the Conversion

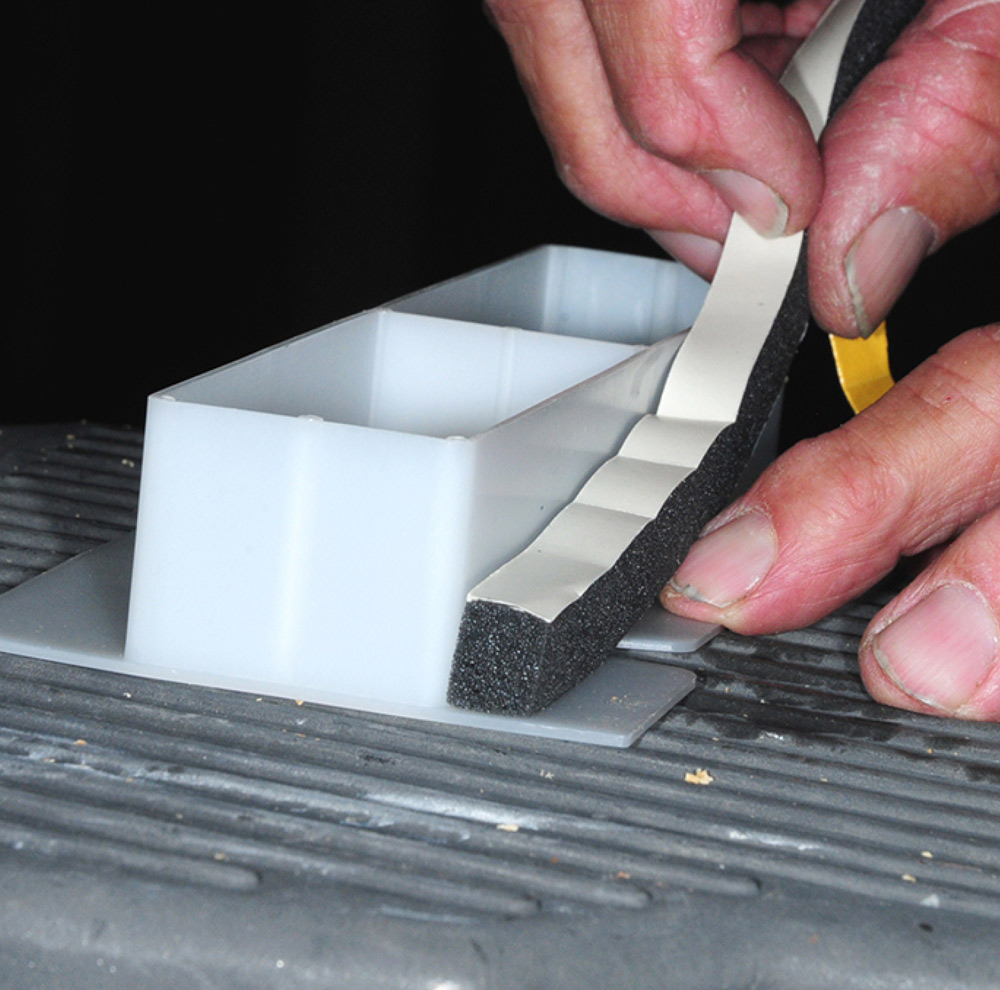

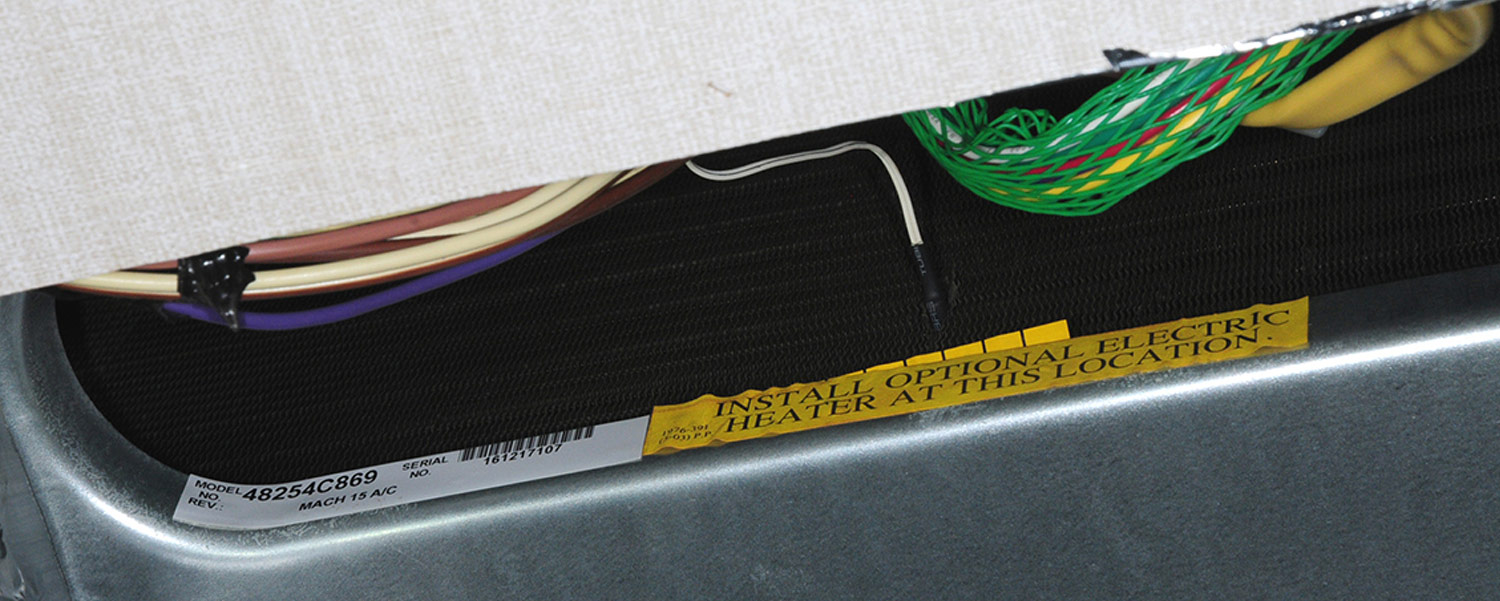

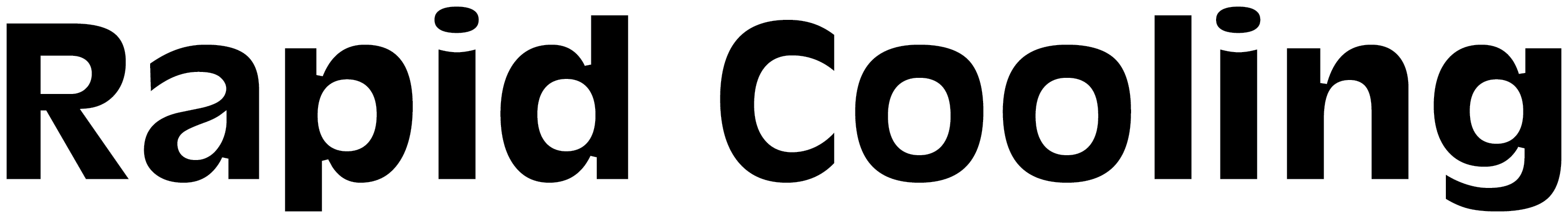

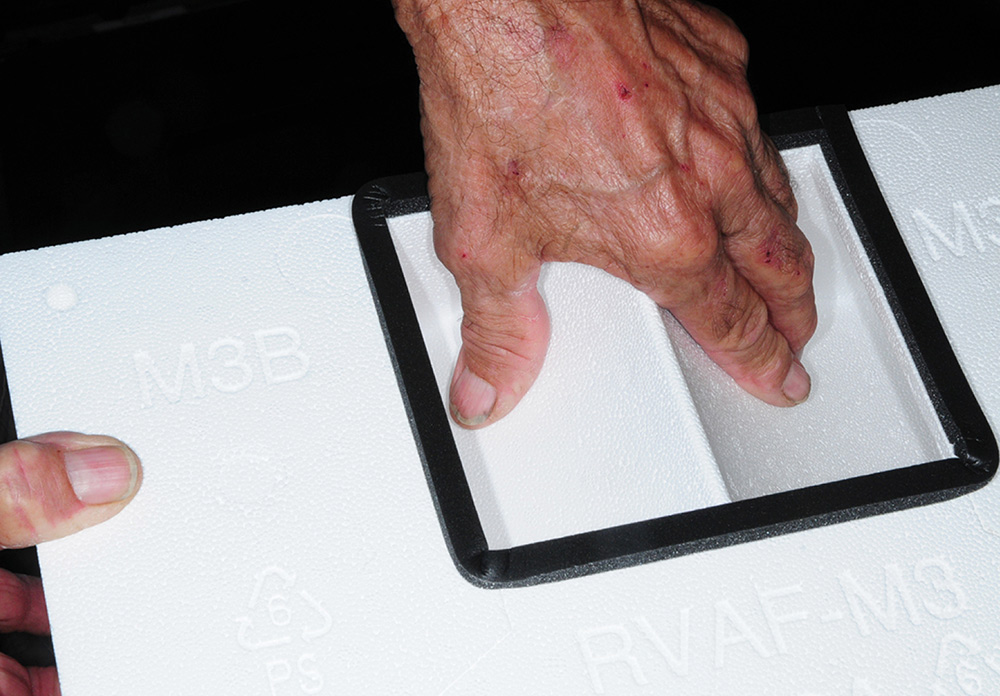

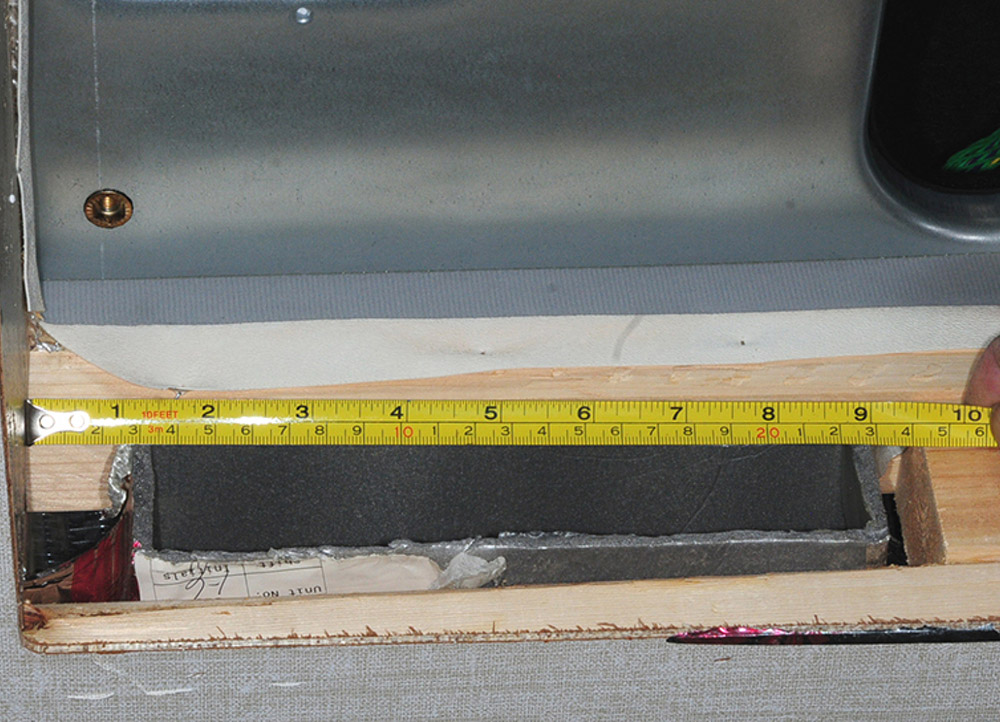

When I opened the box with the RV Airflow Systems kit, I could see that it was quite simple to install. For this project, two kits were ordered for installation in a 2017 Grand Design Solitude fifth wheel that was equipped with two Coleman Mark 8 series air-conditioners, both rated at 15,000 Btu. This 38-foot fifth wheel is located in Palm Springs, California, one of the hottest places in the United States. The RV Airflow Systems AFS foam is designed to be installed by a do-it-yourselfer and will probably take around 1 ½ hours. The instructions are easy to follow, and the company offers a comprehensive video on its website that dispels any mystery to the installation.

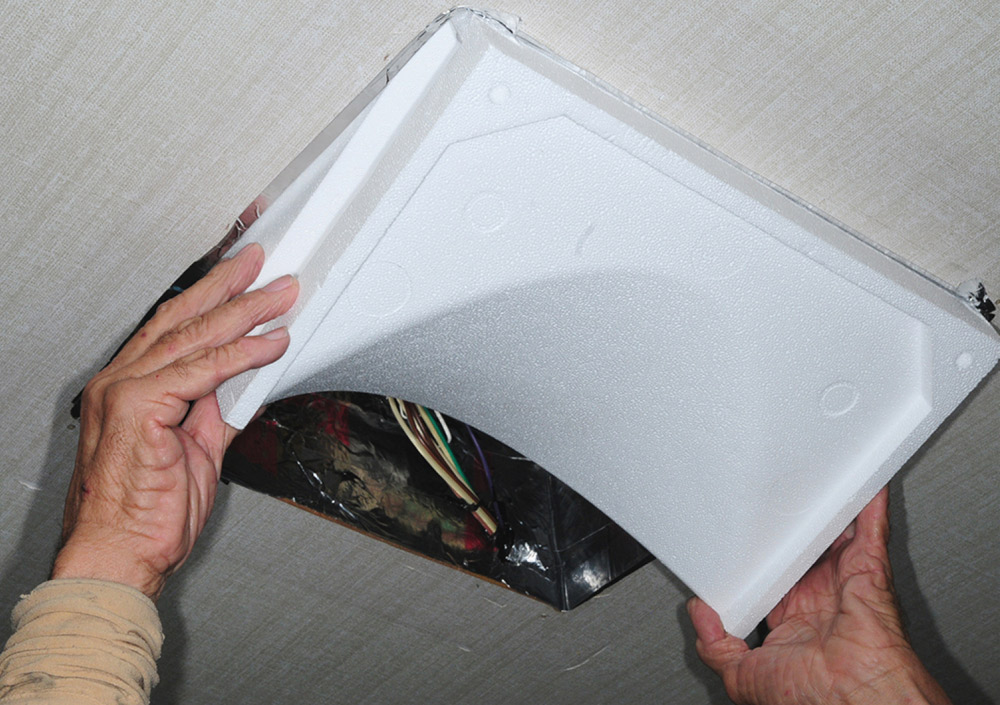

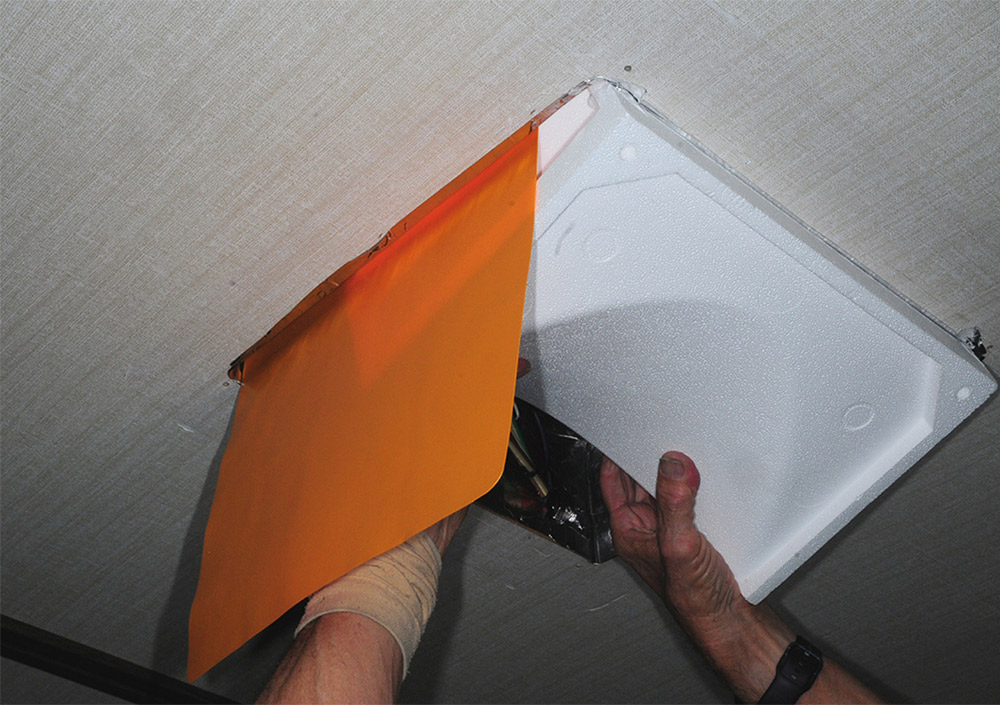

Once the ADB was dropped and the air-shower plate removed, it was noted that the divider between the return air cavity and plenum was never securely attached and air pressure had been pushed halfway into this cavity. This caused the return air to pull in part of the cold air from the plenum, creating far less efficiency. Had this fifth wheel been in a humid climate, quite a bit of frost and ice would have built up on the evaporator. The separator was discarded for this installation, so this issue was solved.

Finally, the lag bolts were pushed through the mounting plate and AFS foam and tightened. It’s best to start with one bolt in one corner; this is much easier with two people. The three remaining lag bolts were then inserted. These bolts are typically much longer than necessary so a socket-and-ratchet or a drill motor will speed up the process to pull the mounting plate up. Just be sure that you do not over-tighten the lag bolts; they only need to be tightened to 20 in.-lb., which is roughly five or six turns once the bolts are snug. You can tighten them a few more turns, if necessary — again, just make sure you don’t damage the AFS foam. Basically, the upper unit seal on the roof must be tight enough to prevent water leakage.

Before re-installing the ceiling assembly/ADB, the air-shower plate was discarded. On some models, there may be a few dog ears on the ceiling plate that will need to be flattened to prevent damage to the AFS foam.

Right from the get-go it was obvious that airflow was stronger than before the installation of the AFS foam modification — and it was quieter. Both the rear and front air-conditioners were checked with a decibel meter before and after the installation. At the ADB, noise level was reduced from 83.5 to 76.3 decibels. While sitting on the recliners in the living room, the noise level went from 69 to 63 decibels. Lying in bed, the noise level from the bedroom air-conditioner was lowered from 69.4 to 68.2 decibels.

Most impressive, however, was the aforementioned increase in airflow. While the company claims improvements of 40%-50% on most conversions, we had no way to really test this other than seat-of-the-pants, but it was immediately noticeable. For an investment of $180 for each air-conditioner and a couple hours of time, the addition of the RV Airflow Systems AFS foam insert can easily substantiate the company’s claim of “it’s like having a second or third air-conditioner.”