Photos by the author

ost motorhomes, trailers and truck campers have some form of comfort heating to maintain interior warmth during cold days and nights. The vast majority of RVs use a forced-air furnace complete with a network of ducting that runs through the floor or cabinetry, terminating with registers to distribute warm air.

Unfortunately, annual furnace maintenance and cleaning are often overlooked, which can lead to poor performance, malfunction and even failure. And — you guessed it — problems seem to only crop up when you need heat the most. Annual cleaning is important because the return air system does not include a replaceable filter to prevent dust, lint and pet hair from impacting performance and safety. Following these preventive maintenance procedures will give your heating system the advantage during the cold weather.

Let’s Take a Look

Using a bright flashlight, peer into the exterior exhaust/cold-air intake of the furnace. You’ll be checking for mud daubers, spiders and wasps, any of which can block the airflow in both directions during the heating process. A restricted airway could cause short cycling of the flame or an improper flame from lack of oxygen, leading to an over rich gas-air mixture.

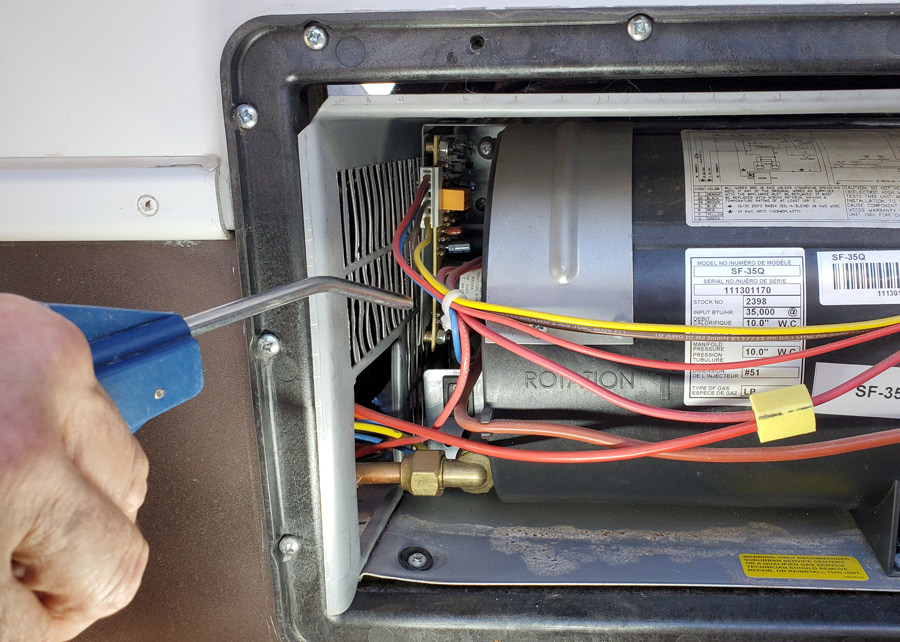

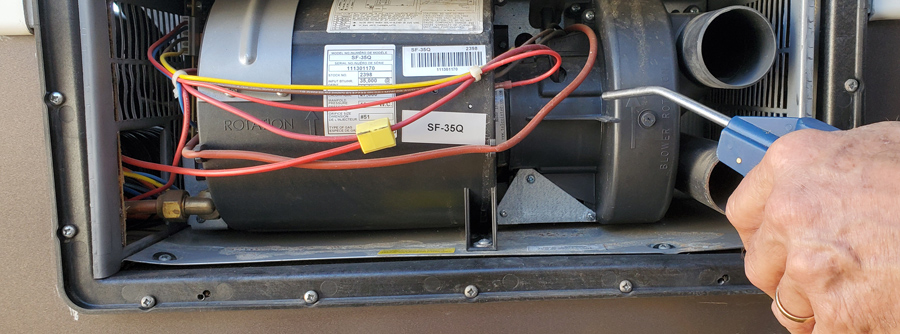

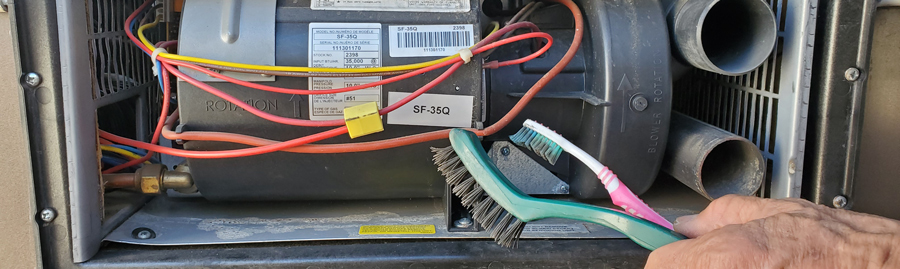

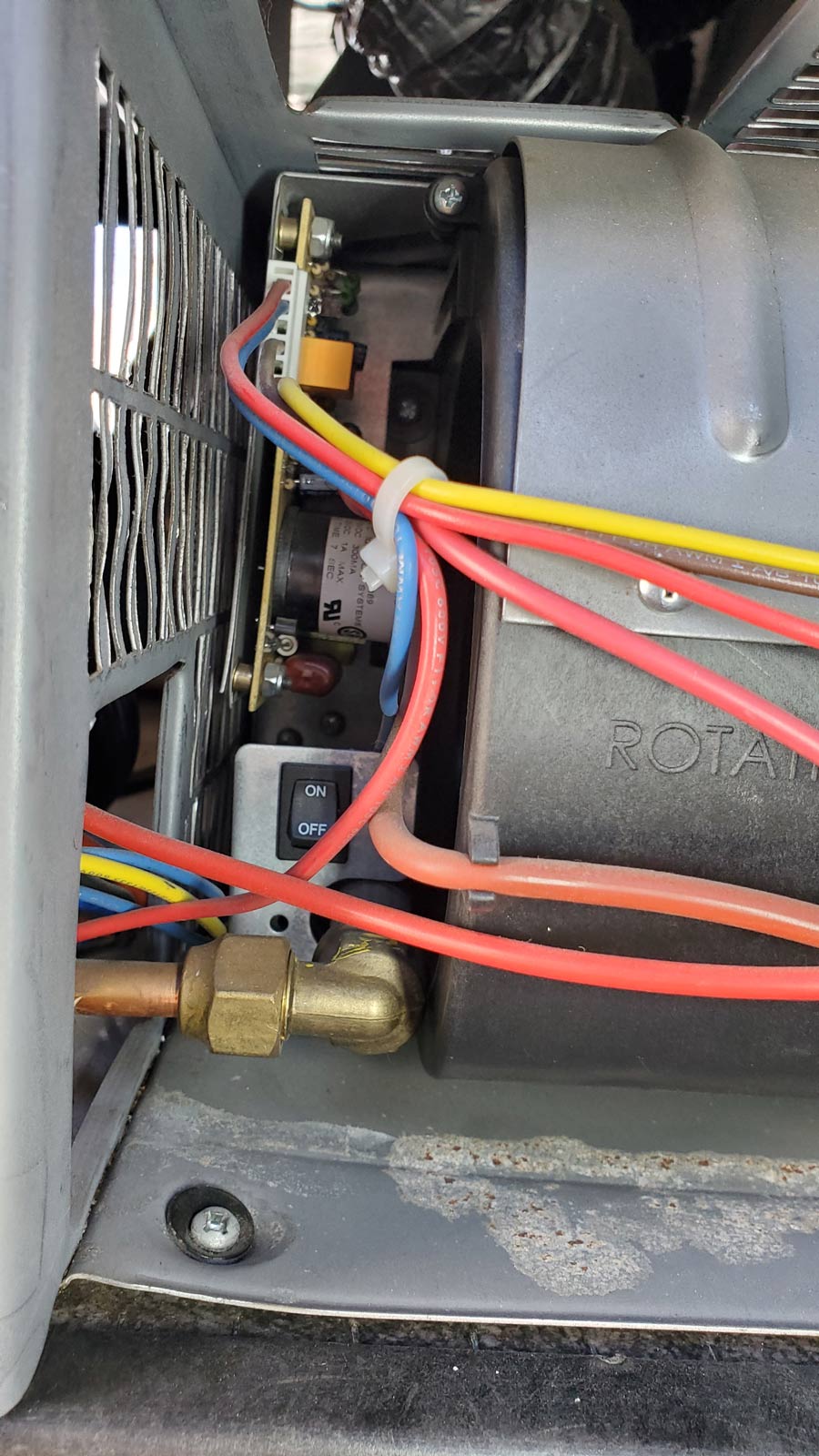

The next step is to remove the interior or exterior access panel for inspection. You’ll be looking for lint, dust and/or debris on the circuit board and blower wheel(s). Be careful not to disturb the wiring or compromise any of the components, which could lead to a furnace malfunction. Use a bright flashlight to inspect the interior of the partially hidden blower assembly to determine if a build-up of lint is present. With the help of a long-nose air nozzle, compressed air (at no more than 125 psi) can facilitate the removal of dust in the hard-to-reach areas. Avoid directing high pressure air toward the circuit board or other electrical components (play it safe and adjust air pressure to 20 psi when cleaning the board.)

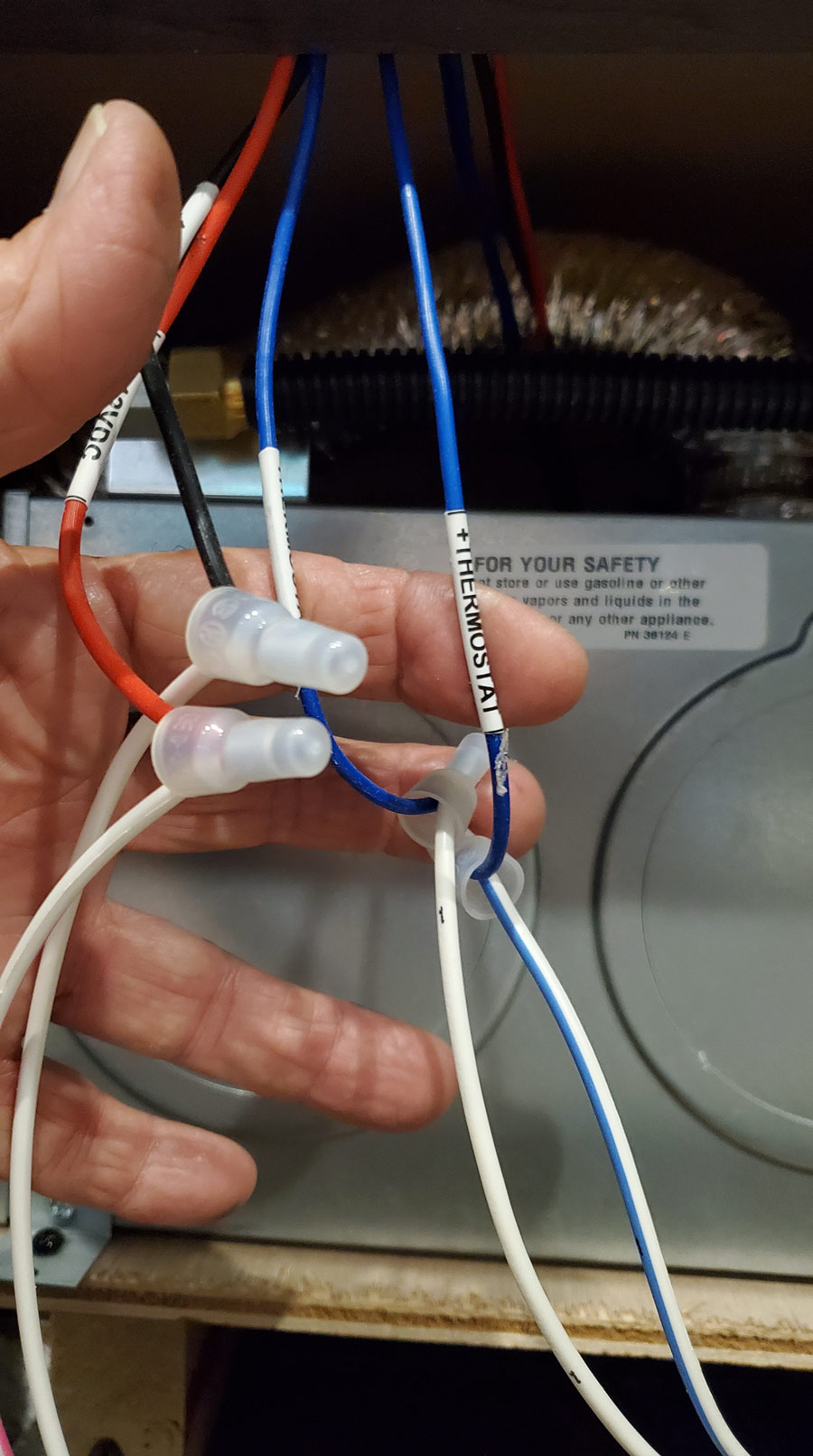

Thoroughly inspect all of the wiring; it is not uncommon for rats or mice to chew through electrical insulation and conduit. Damage to wiring or other components may require the assistance of a certified RV technician.

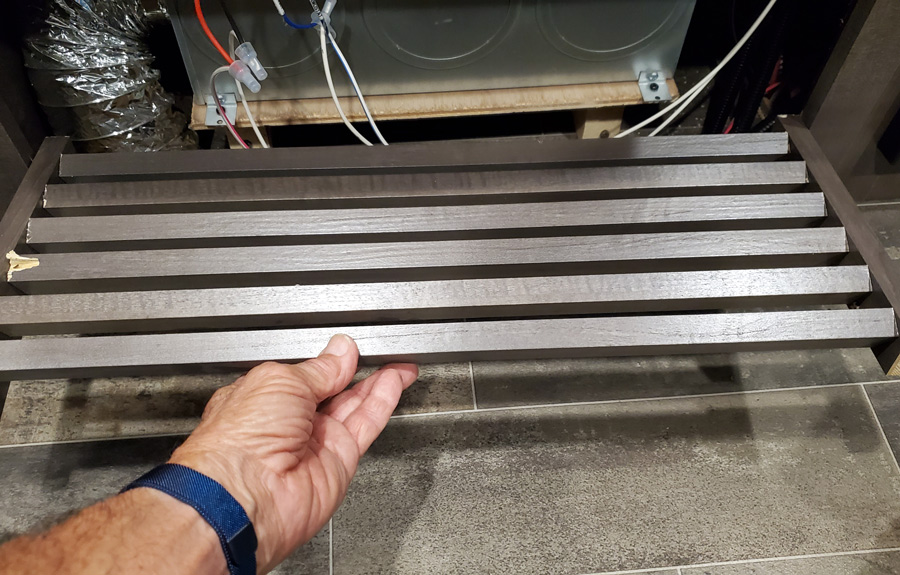

Ducting and heat registers play a big role in heating efficiency. Every furnace is designed to function with a specific number of ducting lengths connected to the furnace body, so don’t use adjustable registers or block off the existing registers. Inspect all accessible flexible ducting and replace if compromised. Floor registers are difficult to clean without removing the covers. Any accumulation of pet hair, lint and other items should be removed regularly with a vacuum cleaner crevice tool.

LP-gas pressure plays an important role during the furnace’s ignition cycle. Not surprisingly, LP-gas regulators deteriorate over time — and any dysfunction will cause improper ignition and air/fuel mixture during the heating cycle. Gas pressure should be checked by a professional technician annually using a tool called a manometer. Not only will this confirm proper pressure, but a leak-down test will discover any breaches in the propane piping and/or fittings. Frankly, it’s not a bad idea to replace the LP-gas regulator every five years. If you are experiencing ignition problems, seek professional help; gas appliances can be dangerous if not diagnosed or repaired correctly.

Battery voltage is critical for the proper function of a forced air furnace system. Check to be sure that all the battery terminals are clean and secure. Using an accurate multimeter, confirm power to the furnace, which requires at least 11 volts DC to operate when the blower is running. Should the voltage drop below that in the middle of a heating cycle, the furnace will go into lockout mode and blow cold air unless the circuit board is designed to shut the furnace off. General battery health is also important to keep appliances, like the furnace, running properly.

Obviously, there are other things that can impact RV furnace performance, from broken connections & errant thermostats to parts that simply wear out over time. That said, proper and timely maintenance can oftentimes reveal minor problems before they became a major headache. Hot water bottles have their purpose — but cuddling up to one because your furnace isn’t functioning shouldn’t be one of them.