oadmaster Inc. of Vancouver, Wash., is well-known for its dinghy towing products — which range from baseplates and tow bars to auxiliary braking systems and more — but the company is fast making a name for itself in the suspension aftermarket for parts such as its Comfort Ride slipper spring and shock absorber kits (available together or separately) for tandem-axle and triple-axle trailers.

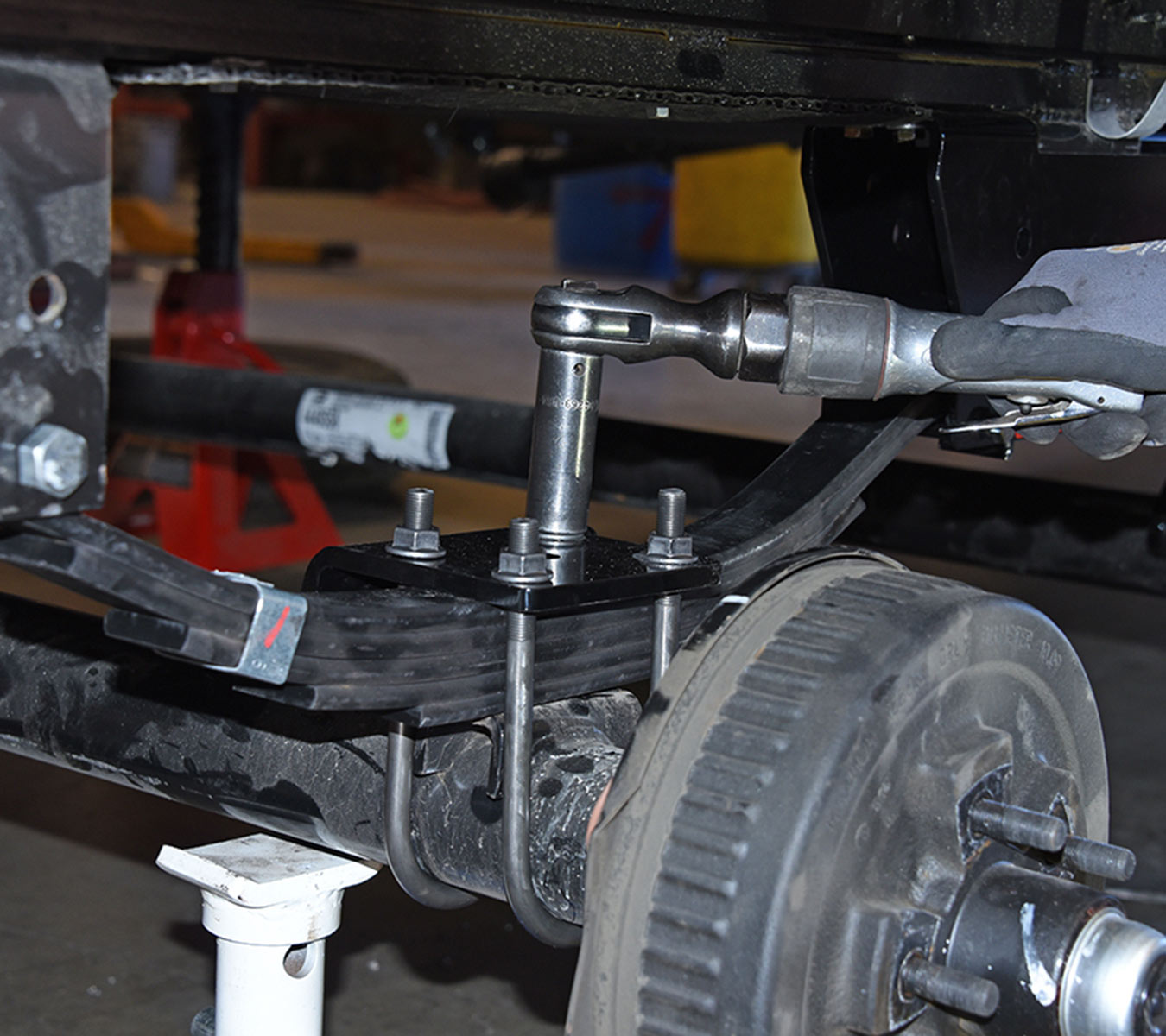

The slipper spring kit is engineered to reduce bucking and bouncing by replacing the leaf spring equalizer (as well as the leaf springs themselves) with a steel box structure that bolts to the equalizer bracket and to the trailer’s frame. The spring box incorporates rollers and wear plates, which are designed to accommodate the specially designed leaf springs.

At one end, the replacement springs have a traditional “eye” that bolts to the spring hangers — but the ends that locate inside the spring box have open, curved ends. The curved ends locate over the rollers inside the box, while wear plates located above these ends keep them properly positioned. As the spring compresses (flattens), the curved ends ride on the roller assemblies, which prevents them from transmitting force to the chassis and to the adjacent leaf springs/axles. To a large extent, this allows each axle/spring assembly to operate independently of one another, instead of transmitting force to each other through the spring equalizer.

As we witnessed when following an installation, swapping for the complete package (including the shock kit) took approximately three hours for a professional tech with air tools; we estimate that a competent DIYer with hand tools could complete the same job in about twice that time, or 6-8 hours (there’s a how-to video on Roadmaster’s website at roadmasterinc.com/products/travel_trailers/comfort_ride.php). That’s a chunk of time, we know, not to mention a significant investment: you can find the slipper springs kit online for about $800-$1,000, depending upon kit size (they are available for axles rated at 5,000-, 7,000- and 8,000 pounds capacities), while the shocks kit will set you back from $400 to $700 (depending upon number of axles). You can also purchase the complete package from places such as etrailer.com. If you use your trailer for more than the occasional weekend outing, however, it’s tough to put a pricetag on the peace of mind which comes from better handling.