he act of getting in and out of a trailer or fifth wheel is not very graceful. Until recently, with the advent of entry step systems like Lippert’s Solid Step and MORryde’s StepAbove that fold down from the doorway and contact the ground to create a stable platform, egress and ingress was relegated to two or three rungs — and, on occasion, sometimes four — that extend from a well under the doorway. Unlike steps that fold from the doorway, the retractable versions can create angst when they flex and wiggle while just hanging in space. While these quintessential steps have provided good service over the years, people still have to watch their footing and acclimate to differences in spacing and step width. The rungs are supported only by a retractable framework and all that flexing can create uneasiness for occupants and even weaken the structure to the point of failure, which can lead to injury.

Owners have devised several ways to stabilize these steps, including the use of blocks, and there are a few commercial products on the market that help somewhat. Recently, Lippert (LCI) introduced the SolidStance Step Stabilizer, which changes the paradigm when it comes to devices designed to provide stability when entering and exiting a towable. The SolidStance bolts to the existing bottom step permanently and its clever design makes it possible to simply fold the legs when it comes time to travel. The entire installation process takes less than an hour and is do-it-yourself friendly.

Prior to starting the installation, familiarize yourself with the instructions, because ultimately you’ll be drilling four holes in the steps and doing it over will result in unsightly extra holes. The instructions may seem overwhelming for such a simple installation, but don’t get hung up on too many details — just be sure to understand orientation. It’s best to hold the hardware in its final location while a helper retracts the steps just to make sure it will close without interference. If it works, you’re ready to measure for the center point on the bottom step and the SolidStance bracket.

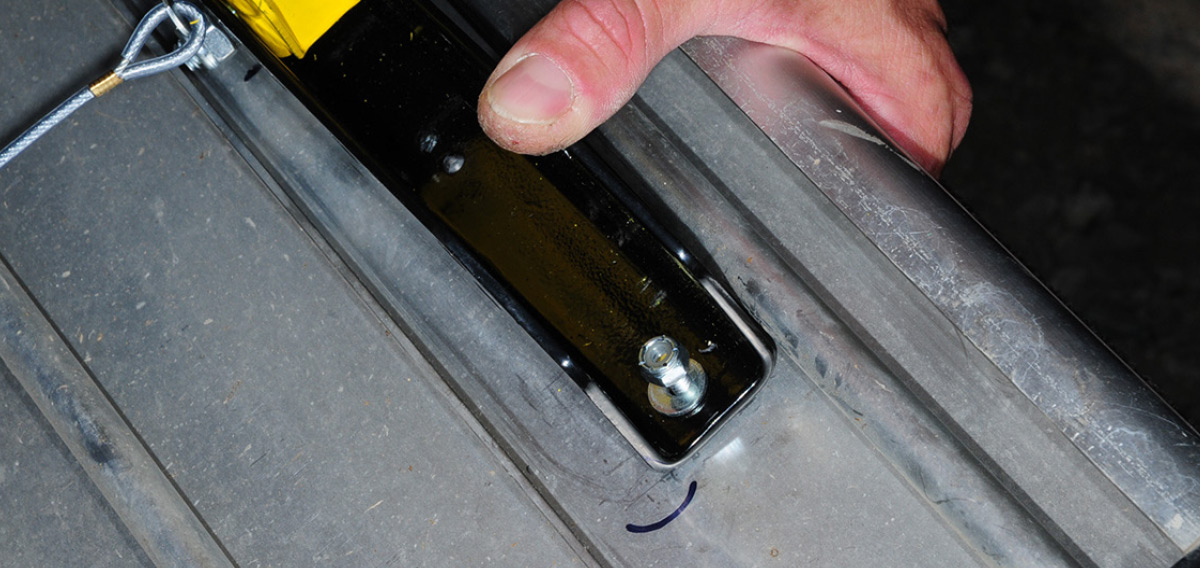

Clamp the SolidStance in place or have a helper hold it steady when marking the locations for drilling the holes to accommodate the provided nuts and bolts. There are two holes on each side of the SolidStance frame that are predrilled.

Once the holes are drilled, it’s simply a matter of bolting the SolidStance to the step using the fasteners, which include locking nuts. Additional larger washers are included if spacing is needed to accommodate any extrusions that might impede proper seating of the stabilizer frame. In this case, the SolidStance fit perfectly in the channel nearest the front of the step. This is not a particularly difficult job as long as you have a helper to hold things in place when tightening the bolts. Figure on less than one hour to complete the project using common hand tools.

There are four drop-leg angles and the inner legs can be extended up to 5 3/8 inches. Before retracting the steps, makes sure the SolidStance legs are in their stored positions and all the pins are secure. Except for the additional weight, the installation of the stabilizer hardware has little bearing on the opening and storing process. The legs will get dirty over time, requiring cleaning with soap and water.

The additional support afforded by the SolidStep is dramatic — something most users will immediately realize if the legs are not deployed after arriving in camp. There’s no flexing of the steps, even while negotiated by heavier-footed people, and that lack of unwanted movement will likely prolong step longevity. Plus, you won’t miss that stomach-sinking feeling that something’s going to give when using the steps.