umans love their shower time. Maybe it’s the comfort afforded by personal time standing under a brisk waterfall of soothing water or maybe it’s a place where new songs are tested. In a stationary home, there’s plenty of water to linger under the shower — but that’s not the case in an RV. Conventional RV water heaters have limited supply, controlled by a LP-gas burner or electrical element. Most can provide 6 to 12 gallons of water, but there’s always down time if back-to-back showers are taken by multiple occupants. Truma’s AquaGo instantaneous water heater overcomes that annoyance by providing all the hot water you want — without interruptions.

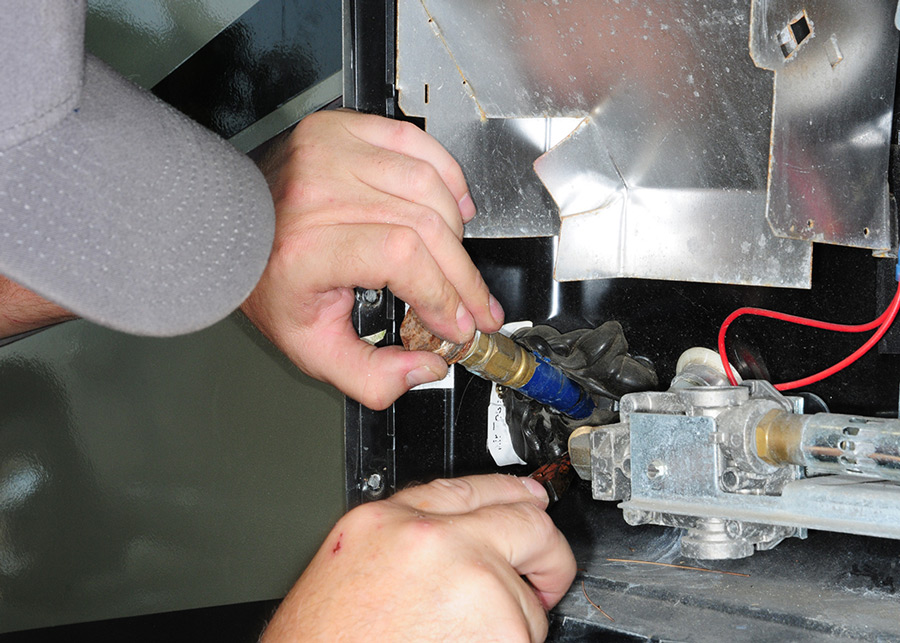

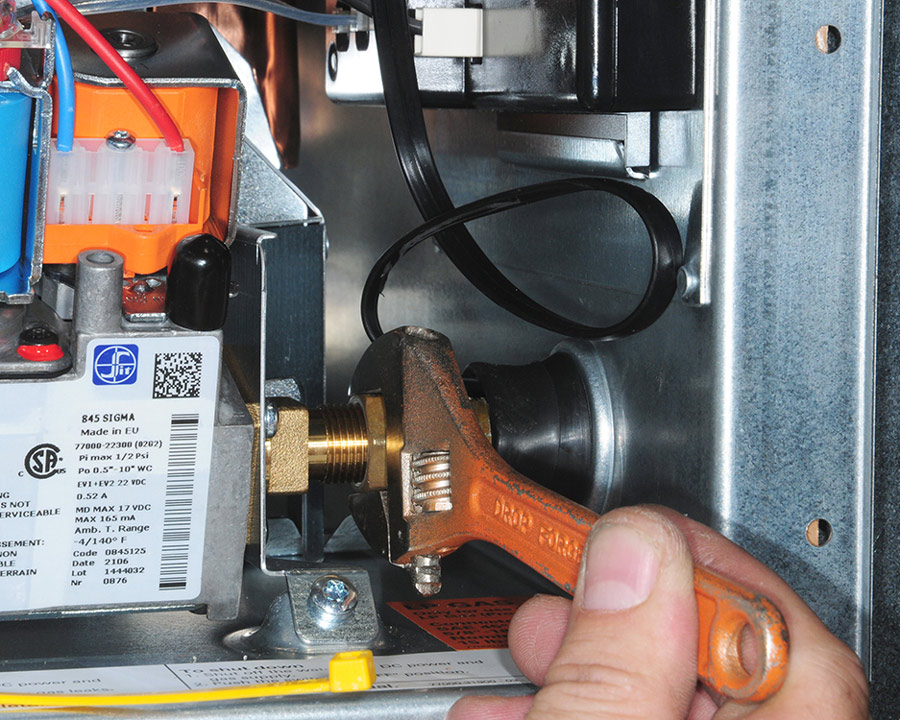

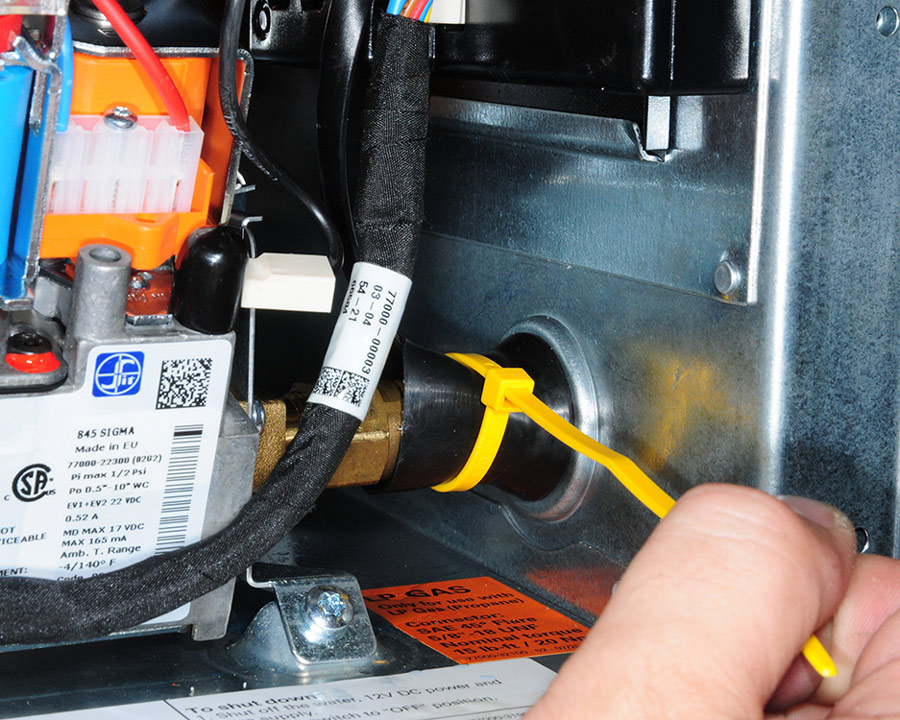

There are several manufacturers who include the AquaGo as part of their build, but for those who would like to upgrade, one of these sophisticated water heaters can be retrofitted by Truma at its Elkhart, Indiana, facility or by one of its certified dealers scattered throughout the country. Truma (www.truma.net), a company with a huge presence in Europe (headquarters in Munich, Germany), does not sell the AguaGo to the aftermarket unless the unit is being installed by one of its trained technicians.

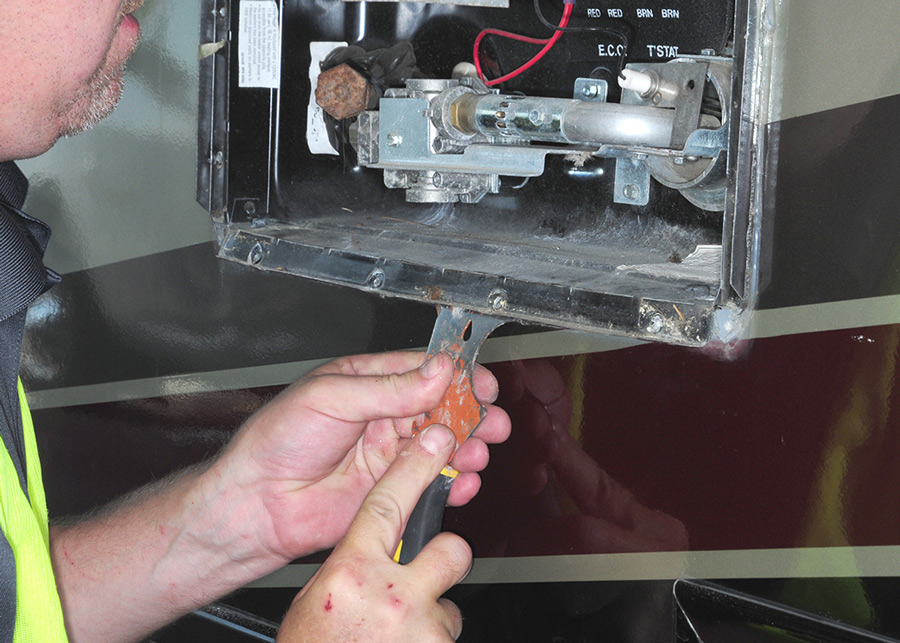

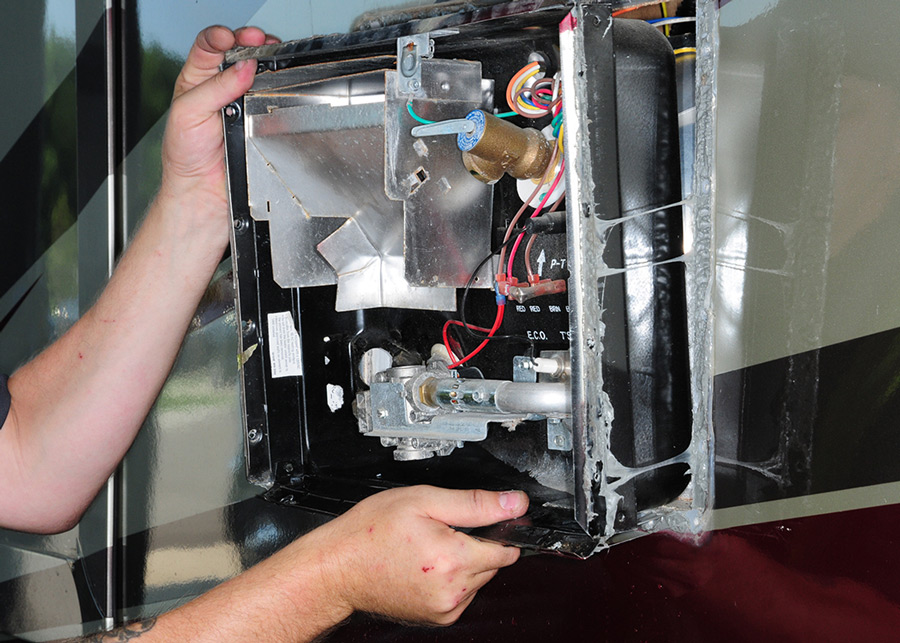

German engineering really comes into play with the AquaGo. The Germans have a reputation for building sophisticated machines (think cars) with redundant features that assure quality and longevity. In that vein, Truma also designed this unit so that it can be retrofitted into any opening that housed a 6, 10 or 12-gallon RV water heater without making any modifications to the original compartment and/or sidewall. What’s really impressive, though, is the manufacturing process — where every component is coded and captured on a computer program that keeps tract of each water heater built and its respective parts. If something goes wrong (which is rare), the water heater can be connected to a diagnostic computer that will identify the issue on the spot and pinpoint the offending component by serial number so that, if need be, a technician can take immediate corrective action. Every unit also is bench tested before being boxed for shipping.

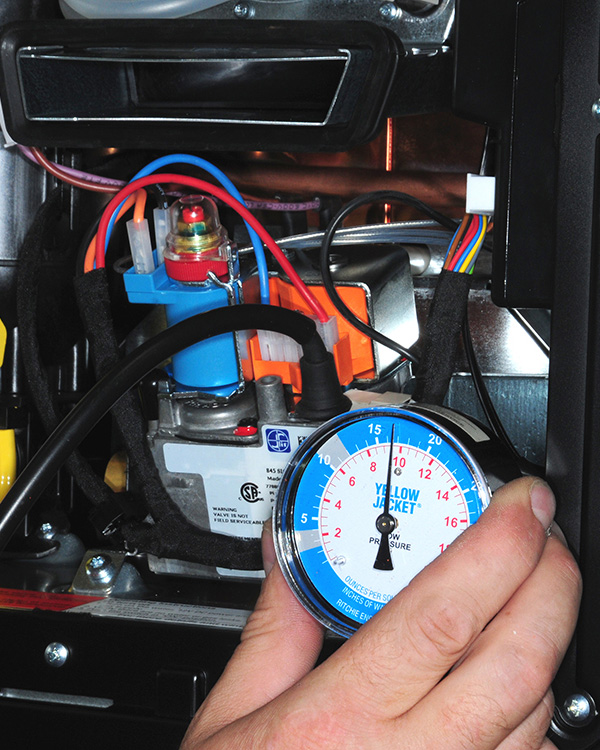

The operation of the AquaGo is straightforward. When water is detected by the volume-flow sensor (which responds to an open faucet), the LP-gas burner is fired up and the water is heated instantly; there is no reservoir that holds heated water that eventually cools and needs to be heated again. The water temperature is regulated not to exceed 120 degrees F., which prevents scalding as long as your skin is not exposed to unmixed (with cold) hot water for more than five minutes. This safety feature was tested multiple times to assure compliance.

The AquaGo only operates on LP-gas, other than the control board that requires 12-volt DC power. I had one of the original units installed five years ago and not only is it still working perfectly under full-time service, but propane consumption is also amazingly low. Based on my usage, a 7-gallon cylinder will last for at least three months (the LP-gas furnace is rarely turned on and all the other appliances in my rig are powered by electricity).

The exterior door of the AquaGo is also designed to flow fresh air to the burner and exhaust any gas in an efficient manner via an integrated ventilation grid. And it looks nice, too — trim plates are used to provide an OEM look.

Beyond the water temperature regulator, a number of other features are integrated into the system for safety, including provisions to monitor voltage, current, fan operation and flame condition. If current goes too low or high, the unit will shut down, and there is even freeze protection built into safety programming. If there’s a problem, like LP-gas interruption (empty cylinder or tank), a light in the control panel knob will flash to provide a code, which can be crossed-referenced by legends on the Internet or in the instruction book. This same knob will also tell you when the unit needs to be decalcified, a process that’s required every year in our fifth wheel based on notification from the control panel. Decalcification frequency, of course, depends on water quality and usage of the RV.

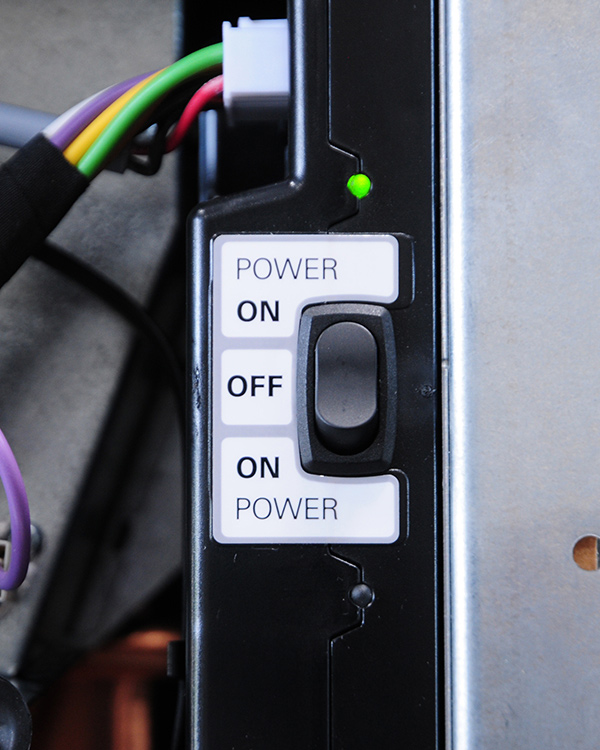

Truma offers the AquaGo in two models: the Comfort and Comfort Plus. In the Comfort model, users can choose Eco or Comfort modes. When in the Comfort mode, water is automatically held at 102 degrees F, which provides hot water to the faucets more rapidly. The Comfort Plus model is only available to OEMs; the system allows hot water to be maintained at full operating temperature for a super-quick flow to the faucets. In this mode, the unit will automatically heat the water in short bursts throughout the day to maintain the proper temperature. If you want to conserve 12-volt DC power and LP-gas while boondocking, leave the switch in the Eco mode but you will use more water, depending on distance from the water heater to the faucets/showerhead.

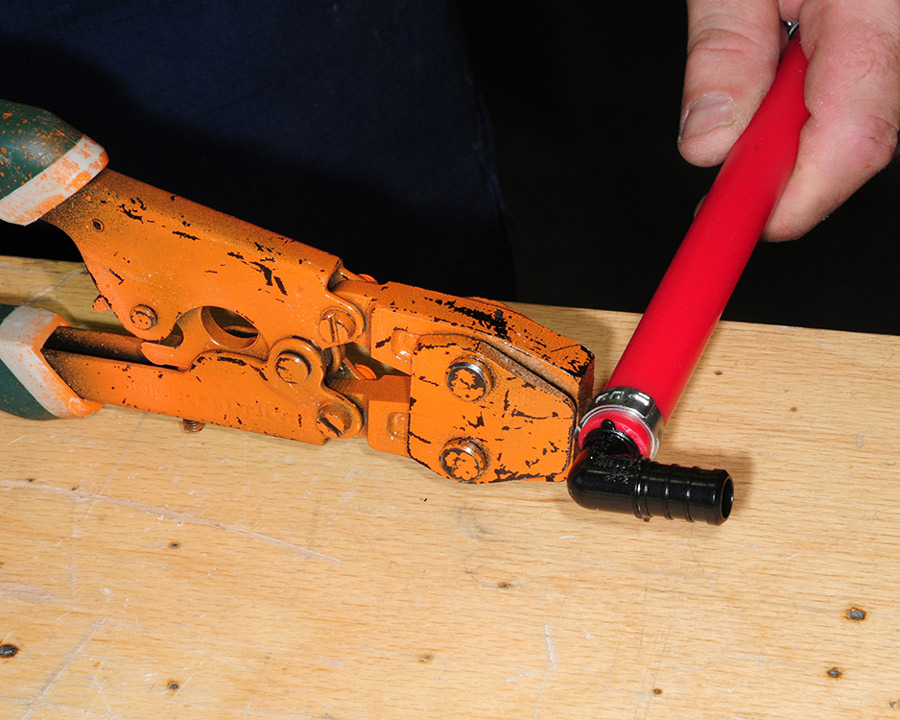

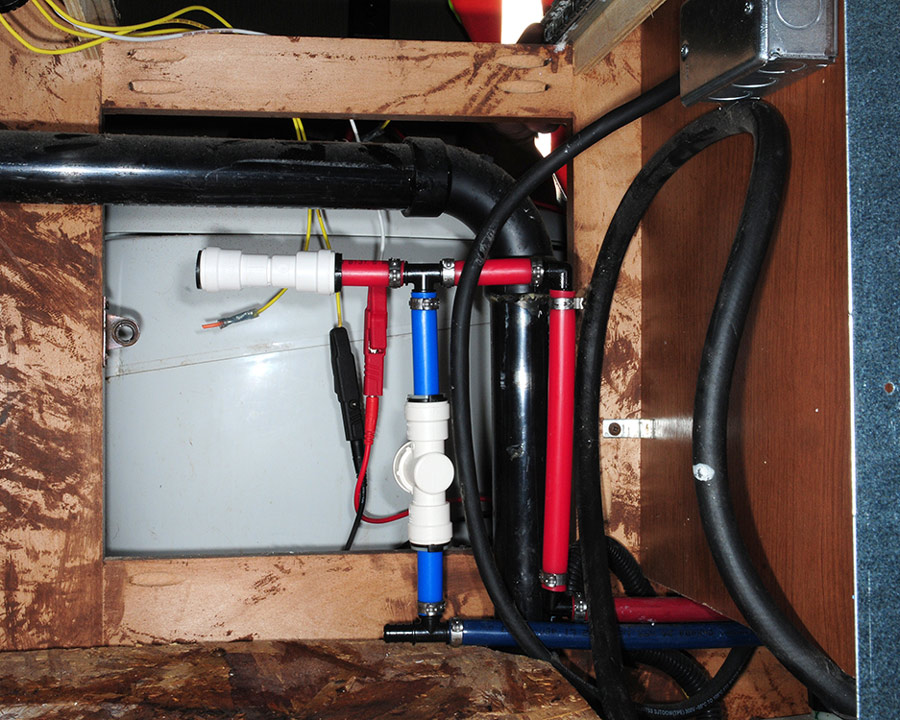

Other than the decalcifying process, there’s not much to service — and what there is to do is really simple. Water can be drained from the tank via a “snout” that is released and rotated down. Since there is no tank to speak of, don’t expect too much water to be drained. Just make sure the water heater is in the Off position and that the water has had some time to cool — if you don’t follow this procedure, expect to get wet from pressurized water. Also, there is a reusable filter in the snout that can be cleaned. When performing decalcification, tablets (available online from Truma) are stacked into the filter opening and the knob is turned to the Clean detent in the remote panel. The whole process is fairly simple once you’ve done it; following the overwritten instructions provided online or in the owner’s manual can be confusing.

The AquaGo is a product you’ll likely never stop bragging about. Granted, it’s more costly — about $0,000, plus $000 for labor — but the reliability factor and convenience afforded by endless hot water are well worth the investment. Who knows — you probably will have enough time in the shower to learn new songs.